Aluminium Metal Injection Moulding promises new opportunities for industry

May 19, 2016

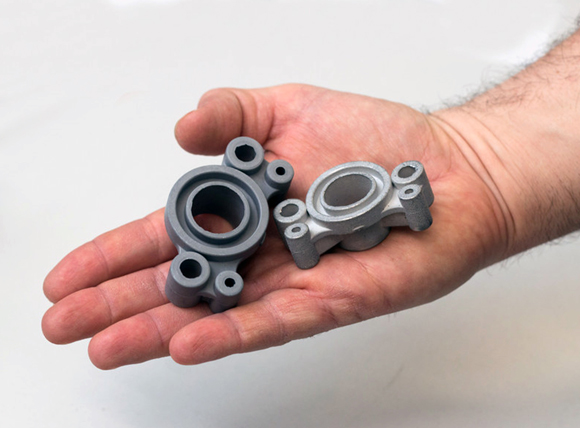

A green aluminium MIM part, left, and the sintered part on the right

Although Metal Injection Moulding has worked very well for many decades for a wide range of metals and alloys, the process has always proved to be unsuitable for aluminium. However, researchers at the Technical University Vienna (TU Wien) have now succeeded in developing a Powder Injection Moulding process for aluminium which can be used to manufacture complex-shaped, weight saving components in a material-efficient manner. This, it was stated, will be of particular interest for sectors in which weight-reduction plays an important role, from the automotive industry to aerospace and space technology.

The team at the Institute of Chemical Technologies and Analytics at TU Wien has been researching sintering technologies for many years and has worked together with some of the world’s leading Powder Metallurgy companies in the field with great success. “The raw materials in Metal Injection Moulding are fine metal particles that react with the oxygen in the air and are therefore usually coated with a thin oxide layer,” explained Dr Christian Gierl-Mayer. In conventional Metal Injection Moulding, the metal powder is first mixed with a binder in order to make it mouldable and this is then injected into a mould. The resulting semi-finished product, known as a green part, is then heated in a sintering furnace. In this way, the binder substance is removed and, at high temperatures, the oxide layer is reduced. The metal grains come into direct contact and join to form a solid metal body.

However, a problem arises if aluminium is used, as the oxide layer surrounding the aluminium particles can only be removed at extremely high temperatures. At the same time, aluminium has a relatively low melting point, which restricts the maximum sintering temperature. It is therefore impossible to remove the oxide layer on the aluminium powder before the entire metal piece has melted.

The binder material, which bonds the metal powder in the PIM feedstock, is also removed by thermal processes, which only occur at increased temperatures. The overlapping of the temperature ranges for binder removal and sintering means that residues of the binding agent are incorporated into the sintered workpiece if aluminium is processed using the same technique as for other metals.

TU Wien has now succeeded in finding a solution to this problem. The key is in creating the correct atmosphere in the sintering furnace. A low-oxygen environment is usually used to prevent the complete oxidation of a metal powder. By contrast, with aluminium, an oxygen-rich atmosphere has been found to be beneficial. “The aluminium oxide layer of the particles is so thick that the particles are protected from complete oxidation. At the same time, the oxygen aids the combustion of the carbon contents of the binder material,” explained Gierl-Mayer.

After this first step, the oxygen atmosphere is replaced by nitrogen and the temperature is increased further. With the additional help of magnesium, the aluminium oxide layer is finally broken and reduced. A liquid phase occurs and the aluminium particles are sintered to form a solid metal piece. “This method allows us to separate the two process steps; the removal of carbon residue and the sintering of the aluminium particles, thereby enabling both steps to run to completion for the first time,” explained Christian Gierl-Mayer.

The Powder Injection Moulding process enables complex shapes to be manufactured, which cannot be realised in any other way, or only with great effort. The aluminium powder is relatively inexpensive, which means that even large components, by PIM standards, can be produced at a reasonable cost. In mass production, savings of up to 50% can therefore be expected on materials and weight compared with conventional production.

There are many potential industrial uses for this new aluminium sintering method. Gierl-Mayer stated, “Sintering processes with other metals have already asserted themselves in many areas of industry, with Austrian companies taking the lead globally in this field.” The low density of aluminium makes it of particular interest for many applications, including in the automotive industries and aerospace engineering, for example, where weight reduction is important. It was also suggested that this aluminium sintering method could open up new opportunities in the areas of machine tools and watches.

A patent application has been submitted for the new technology.