Metal Injection Molding: A revolution in precision component production

Powder Injection Molding (PIM), comprising Metal Injection Molding (MIM) and Ceramic Injection Molding (CIM), is an advanced manufacturing technology for the production of complex, high volume net-shape components.

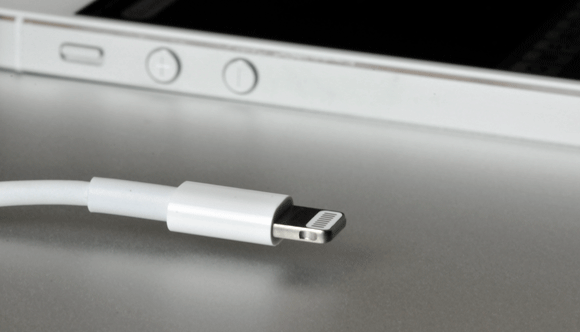

You can find the products of this industry, with global sales estimated to be approaching $5 billion a year, applied in all areas of life, from medical devices, to automotive and aero engines, watches, power tools, orthodontics and consumer electronics.

Introduction to Metal Injection Molding:

Process, Materials & Applications

In our Introduction to Metal Injection Moulding you will discover more about the process steps for metal and ceramic injection molding.

We also look at a range of materials that can be processed, basic properties and some applications for the technology.

- Introducing a dynamic global industry

- An overview of the Metal Injection Moulding process

- Powders for Metal Injection Molding

- Binders and binder removal techniques

- Feedstock for MIM

- Injection Moulding MIM parts

- Sintering in the MIM process

- Applications: Medical and Orthodontic

- Applications: The Automotive Industry

- Applications: IT, Electronics and Telecomms

- Applications: The Aerospace Industry

- Applications: Consumer Products

- Applications: Firearms and Defence

- Conclusions

Metal Injection Molding:

A guide to the technology for end-users and designers

If you are considering Metal Injection Molding (MIM) or Ceramic Injection Molding (CIM) for the production of your components, take a look at our extensive design guide for end-users.

Essential information is provided on what an end-user needs to consider when looking to use the Powder Injection Moulding (PIM) route for the production of components.

- Introduction

- When is a part suitable for PIM

- Optimising your design

- Further design considerations

- Materials and Properties

- Tensile Properties

- Cost, Delivery & Flexibility

- Key criteria for selecting PIM

- References

Discover the latest issue of PIM International

Download PIM International magazine