Yxlon launches new x-ray and CT system for non-destructive testing

June 16, 2020

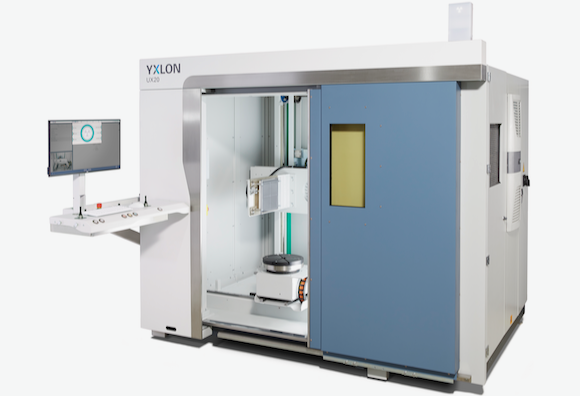

Yxlon International, a company of the Swiss Comet Group and designer and producer of radioscopic and CT inspection systems for a variety of applications and fields, has released its new universal X-ray and CT system, the Yxlon UX20. According to Yxlon, the system’s operation requires no specialised X-ray knowledge, enabling it to be used by even untrained personnel to achieve optimal inspection results.

This is said to be made possible by the company’s Yxlon Geminy software platform, which combines all the programmes involved in inspection. Offering intuitive menu navigation, numerous pre-settings and the ability to switch rapidly between radioscopy and computed tomography, non-destructive testing can be performed quickly and easily.

UX20 is suitable for the inspection of a range of components., using its advanced CT functions parts of sizes up to 800 mm in diameter and 1100 mm in height can be inspected reliably, with a height-adjustable operator work area directly attached to the system.

Having a compact footprint, the UX20 is said to be specially designed for use in harsh environments like foundries in the automotive and aviation industries. Components such as the generator, cooler and high-voltage cable are integrated into the cabin for protected and extended use, while remaining easily accessible for maintenance work.