Retech adds new manufacturing facility at headquarters

May 24, 2023

Retech, a Seco/Warwick Group company based in Buffalo, New York, USA, has announced it will be expanding into a second location some 60% larger than its current building, which it moved into just five years ago.

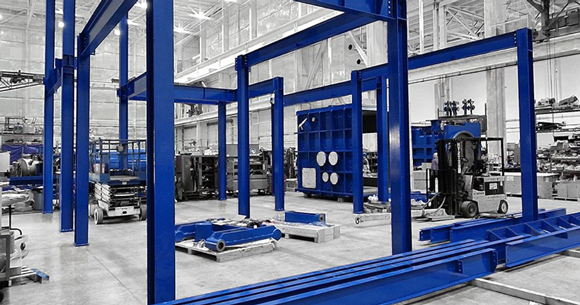

The new 6,500 m2 facility will house fabrication, welding, small assemblies, and other manufacturing machinery, which is able to be moved in as soon as possible. The current building, which the company will continue to occupy, will house the R&D operations, large assemblies, and factory acceptance testing operations.

Retech will also be increasing staff, with an estimated thirty to sixty new employees required at various levels.

“When we moved into our new Buffalo headquarters, we anticipated an upward trajectory, but this really exceeds expectations. This move puts us at 113,000 total square feet of R&D, manufacturing, assembly, and storage space, which allows us to stay ahead of that growth instead of catching up to it,” stated Earl Good, Retech Managing Director.

Now in its sixtieth year, Retech utilises melting technologies in combination with gas atomisation, spin cup atomisation or a spin wheel to produce powders, and supplies post-atomisation, powder handling and consolidation equipment.

Download PIM International magazine