Metal Injection Moulding: Building on solid foundations in the medical sector

For applications that require higher density levels, the Hot Isostatic Pressing (HIP) of MIM parts, particularly for the medical sector, has become a popular and effective post-processing solution. In MIM medical applications, fine sub-surface porosity exposed during machining and finishing operations is regarded as a harbour for bacteria and the elimination of the risk of infection in the operating theatre has been a driving force large enough to justify the additional cost of HIP, even when the elimination of porosity is not required to meet mechanical property specifications.

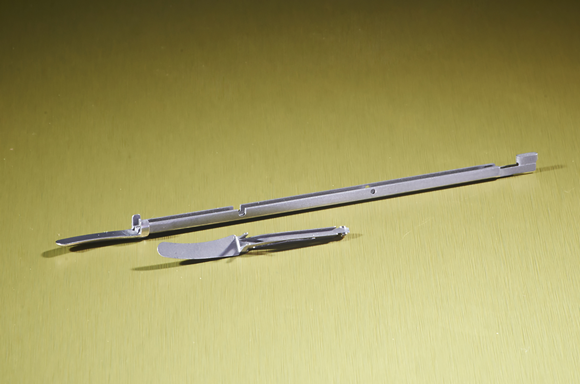

Fig. 4 These two 5 mm tines manufactured by FloMet LLC, an ARC Group Worldwide company, won a MPIF Grand Prize in 2014. The tines, one fixed and one moving, are used in a thermal tissue fusion and dissection system made by ConMed. Fabricated by MIM from 17-4 PH stainless steel, the manufacturer overcame many moulding and processing challenges, including the fixed tines’ length and thin-rib requirements, as well as the need for straightness over the part’s entire length (Courtesy MPIF)

“Another misconception is that MIM creates parts that have deep voids or cracks in them. With the advancement of the technology, these types of defects can be processed out during the validation phase of part development. Once the processing parameters are locked in and monitored, the risk of these defects can be significantly reduced or eliminated,” stated Houck.

Commenting on the awareness of MIM in the medical sector and trends that are driving the adoption of the technology, Krishna Chivukula Jr., CEO of Indo-US MIM Tec Pvt. Ltd., stated, “Internationally, I believe that awareness is excellent. However, the medical device industry is inherently conservative and resists change for a variety of reasons. However, attendant cost pressures associated with aging populations are forcing them to evaluate MIM more aggressively. That said, I believe MIM’s adoption for medical devices is not primarily driven by awareness but by the domestic environment in which device companies operate in this environment is different in every country.”

North America

The number of Metal Powder Industry Federation (MPIF) award winning MIM medical components over the last decade reflect the importance of the technology to the medical sector as well as the innovations and cost-savings it enables. A selection of these parts can be seen in Figs. 3-6, 8 and 17.

Fig. 5 Polymer Technologies Inc. received an MPIF Award of Distinction in 2013 for this stainless steel shuttle used in a smart stapling device for both open and minimally invasive arthroscopic surgery. The shuttle incorporates two separate components that were previously combined via laser welding. Making this intricate, small and lightweight 4.9 g component presented many challenges, including the extremely thin walls, tight radii and true position geometries. Properties include 7.75 g/cm³ density, 200,000 psi UTS, 160,000 psi yield strength, 11-30% elongation and 82 HRB hardness (Courtesy MPIF)

Commenting on US market, Indo-MIM’s Chivukula stated, “In the USA the move to single-use devices to reduce liability is forcing components to MIM since small complex parts can be disposed of after one or several uses. Design complexity is also forcing more complexity onto less component real estate, which increases the cost of machining and reduces the viability of disposing of the component when the industry is under cost pressure…

To read the entire article, download the FREE 2017 Spring issue of PIM International magazine:

Download single page edition

PDF (17 MB), single pages, for small monitors and tablets. We recommend saving the file to your computer (right click and choose “save link as”) and viewing with Adobe PDF reader.

Download double page edition

Download double page edition

PDF (16 MB), double pages (spreads) for larger computer monitors. We recommend saving the file to your computer (right click and choose “save link as”) and viewing with Adobe PDF reader

Connect with us on our social media channels

- Previous

- 2/2