XJet to showcase metal and ceramic AM solutions at Formnext

October 24, 2022

XJet, Rehovot, Israel, has announced that its focus at Formnext 2022 will be on demonstrating how manufacturers can achieve green, scalable Additive Manufacturing of high-definition metal and ceramic parts. XJet’s Carmel 1400 uses NanoParticle Jetting (NPJ) powderless technology in an effort to solve challenges in multiple industries.

XJet metal AM machine user Azoth, Ann Arbor, Michigan, USA, will be present on the stand throughout the show, sharing its team’s practical experience and knowledge of working with XJet’s metal NPJ Additive Manufacturing solution.

“We’re seeing high demand for XJet capabilities – fine features, high resolution and good surface finish, right off the printer, which perfectly complements our expertise in metal manufacturing,” stated Cody Cochran, Azoth General Manager and co-founder. “The Carmel 1400M system allows us to go from small volume to full scale manufacturing on the same system, without having to adapt the equipment in the transition to manufacturing.”

Yair Alcobi, XJet CEO, added, “As crowded as the metal AM sector is, XJet technology has something truly unique to offer the market. Sharp angles, overhangs, internal cavities are still often difficult to achieve with other technologies, but because of our unique soluble support material and automated support removal with the SMART Station, these features are no problem for XJet and can be produced repeatedly, reliably and on an industrial scale. Our unique use of material jetting and nanoparticles means we get significantly finer detail, improved surface finish and thinner walls than any other metal or ceramic AM technologies.”

Using nanoparticles and substantially less binder in its process reputedly allows XJet to achieve superior material density and lower sintering temperatures by around 15% for stainless steel, saving energy and subsequently seeing less shrinkage and deformations as the process moves away from the melting point of the metal. In addition, using sealed cartridges for materials is intended to make the Carmel 1400M easy to operate and safe to use.

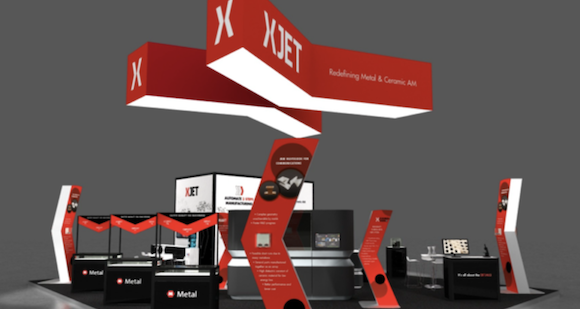

XJet will have its Carmel 1400M AM system running live on stand C01 in Hall 12.0 at Formnext alongside its SMART Station for automated soluble support removal. The company will also display the next developments in its range of materials at Formnext, which currently comprises 316L stainless steel and, in its ceramic range, zirconia and alumina.

“This is the first time the new management team will be at Formnext together and we’re looking forward to meeting with the European AM community and sharing our new vision for XJet,” Alcobi concluded.