UK producer reports strong demand for MIM products

April 14, 2008

Egide, the UK based metal injection moulding (MIM) producer, reported strong demand for metal injection moulded parts in 2007, a year in which they experienced a 25% increase in business. Egide has high hopes of further growth in the region of 40% in 2008.

In response to this strong demand for components, the company has expanded capacity by investing heavily in new equipment, with 6 moulding machines, 5 debinding furnaces, and 4 sintering furnaces now underpinning their capacity.

Egide’s Managing Director, Chris Conway told Powder Injection Moulding International ‘Quality, design ingenuity and a close working relationship with our customers have always been fundamental to our business and our high level of customer satisfaction.

Egide’s Managing Director, Chris Conway told Powder Injection Moulding International ‘Quality, design ingenuity and a close working relationship with our customers have always been fundamental to our business and our high level of customer satisfaction.

Our recent increase in capacity will enable us to further satisfy our customers as we are now able to provide shorter lead-times, which in turn will enable our customers to better meet their customer demands. For us, this is a significant achievement because, as a supplier, we regard ourselves as an extension of our customers business’.

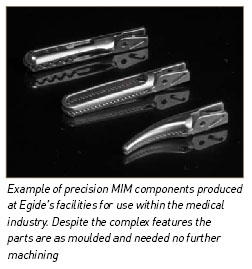

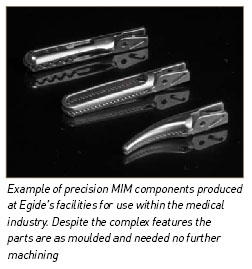

Metal injection molding is Egide’s core business with full in-house facilities from tool design and build, to the compounding of the feedstock, right through to the final sintering. Egide’s Total Quality Manger, Lawrence Reekie stated that tight control at every stage ‘allows us to manage the consistency and dimensional repeatability of the parts we produce enabling us to supply parts of unrivalled quality’.