Production parameters affecting the impact toughness of Metal Injection Moulded parts

June 1, 2015

Whilst a substantial number of technical papers have investigated the influence of sintering parameters and powder loading on the mechanical properties of Metal Injection Moulded (MIM) components, the effects of the different aspects of the injection moulding steps on properties such as impact toughness has been less well reported.

P Pachauri and Md. Hamiuddin at the College of Engineering & Technology, Aligarh, UP, India, have undertaken research to optimise the moulding parameters which would simultaneously satisfy the requirements for quality control of MIM parts in the green state in order to attain the desired impact toughness in the sintered parts. The authors reported on their work in the International Journal of Advanced Materials and Metallurgical Engineering (Vol. 1, No. 1, 2015, pp-1-11).

The controlled parameters used for optimisation in this research include injection pressure, injection temperature, mould temperature, holding pressure and holding time, injection speed, powder loading and cooling time. These parameters have been optimised using analysis of variance (ANOVA) for signal to noise ratios obtained in experiments performed by following a Taguchi L27 orthogonal array.

Results show that the injection pressure, mould temperature and powder loading are highly significant factors with reference to the impact toughness, while the injection temperature, injection speed, holding pressure, holding time, cooling time and the interaction of injection pressure and mould temperature do not show significant effect at 95% confidence level.

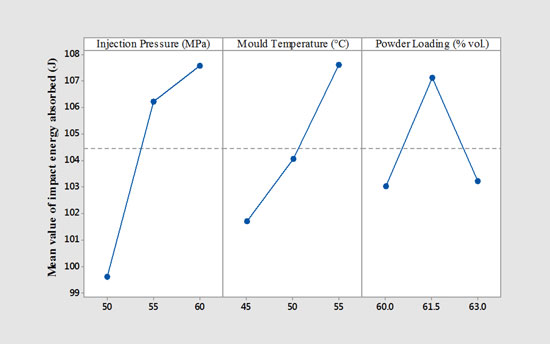

Fig. 1 Main effects plot for mean values of impact energy absorbed (From the paper ‘Optimization of Injection Moulding Process Parameters in MIM for Impact Toughness of Sintered Parts)

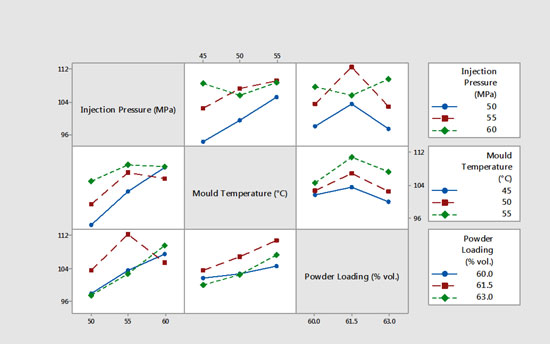

Fig. 2 Interaction plot of injection pressure, mould temperature and powder loading (From the paper ‘Optimization of Injection Moulding Process Parameters in MIM for Impact Toughness of Sintered Parts)

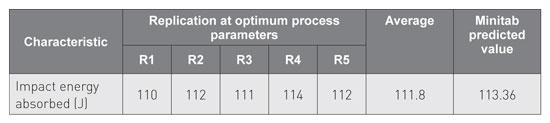

From the experiments undertaken it was found the impact toughness has a maximum value when injection moulding pressure for the 316L feedstock investigated is 55 MPa along with mould temperature of 55°C and powder loading of 61.5 vol%. The level average response required for the analysis of the trend of performance characteristic with respect to the variation of the factors under study is shown in Fig.1 and the interaction plot of injection pressure, mould temperature and powder loading in Fig. 2. It was also found that the average impact energy absorbed obtained in the research is within the predicted 95% confidence value as can be seen in Table 1.

Table 1 Results of confirmation experiments