Multi-frequency vibrating sieves for screening ultrafine powders

December 6, 2016

Fine, spherical metal powders having narrow particle size distributions are often essential in Powder Injection Moulding in order to achieve higher packing density, which in turn lowers binder content in the moulding feedstock. Additionally, finer powders in the as-moulded parts enhance sintering. To obtain particle size distributions in the range from 30 µm to 60 µm powder producers have used ultrasonic sieving techniques and/or air classification, but, for ultrafine metal powders down to 6 µm, which are often required for PIM, existing sieving techniques have not been found cost effective.

The Virto Group/Cuccolini of Reggio Emilia, Italy, is a long established manufacturer of screening and particle separation equipment for all forms of particulates used in a variety of industries ranging from food, pharmaceuticals, metal powders, heavy aggregates and mining. Virto displayed one of its ScreenX Multi-Frequency Vibration (MFV) sieving machines at World PM2016 in Hamburg, which the company stated is able to significantly increase sieving capacity and particle size separation efficiency even for problematic particulates down to 6 µm.

Asad Bilal, Business Development Manager at Virto/Cuccolini told PIM International that the ScreenX MFV equipment has had particular success with fine particle separation of metal powders both at high and lower volumes to a size of less than 10 µm with an efficiency of 99%. He stated that the ScreenX MFV sieving machine achieves far greater capacities for fine and difficult materials due to its patented multi-frequency vibration technology that accelerates the mesh by up to 500 G. This is said to be a 10,000% increase in mesh acceleration compared to standard sieving methods. Bilal said that the 500 G acceleration increases both the amplitude and frequency of the vibration and so doing overcomes mesh blinding, pegging and agglomeration by harnessing the power of resonance to achieve efficient and high capacity wet or dry screening of ultrafine powders.

Fig.1 Multi-frequency vibration sieving machine built by Virto-Cuccolini

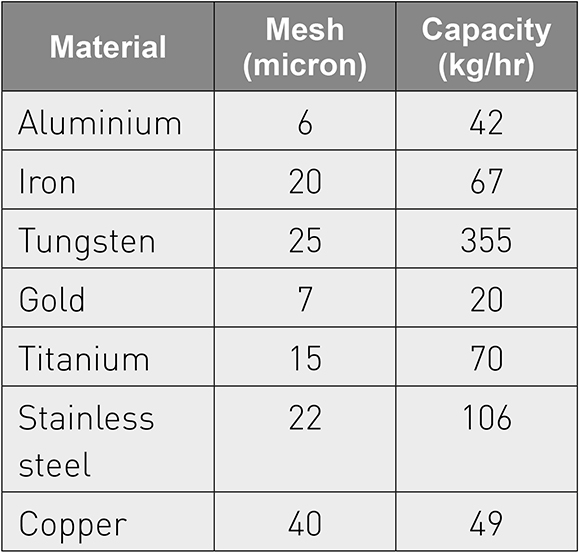

The ScreenX MFV sieving equipment, an example of which is shown in Fig. 1 is offered in rectangular or circular configuration with the circular version available from 650 mm diameter to 1200 mm diameter. Table 1 shows the sieving capacity of a 650 mm diameter machine for different fine and ultrafine metal powders. The company also produces single frequency vibrating sieving machines for all standard separation of powders down to 45 µm particle size.

The sieving capacity of a 650 mm diameter Screen X MFV machine