MTC reports successful conclusion of CASCADE project

June 1, 2020

The Manufacturing Technology Centre (MTC) has reported the successful conclusion of the CASCADE project, which began in 2015, aimed to bring together world-class expertise in metal powder atomisation, metallurgy, and net shape and Additive Manufacturing.

Led by Liberty Speciality Steels (LSS) in Sheffield, UK, the project participants also included research and academic partners from the MTC, industrial partners Johnson Matthey, Renishaw plc, Atomising Systems Ltd (ASL), Hybrid Manufacturing Technologies (HMT) and Farleygreene, as well as research and academic partners at the Advanced Manufacturing Research Centre (AMRC), the University of Birmingham and the Warwick Manufacturing Group (WMG), the University of Warwick via a subcontract.

The MTC summarised its contribution to the CASCADE project in an official statement following its successful conclusion.

The need for a UK-based metal powder supply chain

As metal powders are primarily produced in Sweden and the USA, a UK-based supply chain is needed to service growing market demand. Liberty Speciality Steels, as an experienced manufacturer of highly engineered steels, decided to tackle this need by expanding its capabilities into steel and nickel powder production and sought the MTC’s support to achieve this.

Through the CASCADE programme, LSS and the MTC worked collaboratively with the seven other partners to develop a range of technologies across the metal powder supply chain. Supported by Finance Birmingham via the UK Government’s Advanced Manufacturing Supply Chain Initiative (AMSCI) fund, CASCADE enabled LSS to establish its first powder production facility, which currently has the capacity to accept new orders for delivery in June–July 2020.

The MTC supported LSS in developing powders by providing access to its capabilities, including its powder characterisation labs, industrial-scale Hot Isostatic Pressing (HIP) and Metal Injection Moulding (MIM) facilities.

Project completion

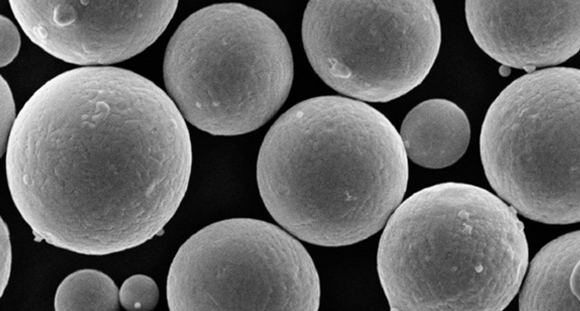

Successful completion of the project has enabled LSS to acquire a vacuum induction melting gas atomiser with an anti-satellite system from Atomising Systems Ltd. The atomiser is capable of producing highly spherical steel and nickel powders with a minimal amount of satellites and improved flowability, making them ideal for AM.

LSS has now established a new business, Liberty Powder Metals (LPM), as a UK-based powder metal supplier and innovation incubator supported by the Tees Valley Combined Authority. Up to fifty jobs are expected to be created as a result of the project.

LPM has also developed the capability to handle and package powders under inert atmosphere to reduce moisture and improve powder performance.

Gill Thornton, Senior Project Manager, CASCADE, stated, “The CASCADE project has enabled Liberty Speciality Steels to establish unique capabilities in metal powder production, characterisation and testing, which is expected to create high-skill jobs in the UK and serve a wide range of high-value manufacturing sectors in the UK and worldwide.”

Simon Pike, General Manager, Liberty Powder Metals Ltd, commented, “This project will be a very significant step forward for the international metals industry. We are very proud to work with valued partners to bring this game-changing innovation to the North East and to build on the excellent foundations laid by the CASCADE project.”