MIM finds applications in optical communication

July 1, 2007

Sumitomo Osaka Cement (SOC) has been producing MIM parts at its Funabashi (Chiba Pref.) site since 1987 with several expansions in capacity since that time.

Sumitomo Osaka Cement (SOC) has been producing MIM parts at its Funabashi (Chiba Pref.) site since 1987 with several expansions in capacity since that time.

According to a SOC technical report from the Metal Injection Team of the Advanced Materials Research Group the company uses its own unique water based binder, which vastly reduces debinderising time compared with conventional heat extraction method, and this has been found advantageous for materials as Covar (Iron-Nickel-Cobalt), Permendur (Iron-Cobalt-Vanadium) and SUS430 and 304L (stainless steel) used to produce optical communications parts which require low thermal expansion coefficients.

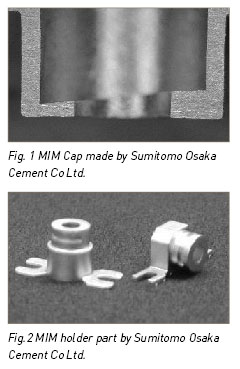

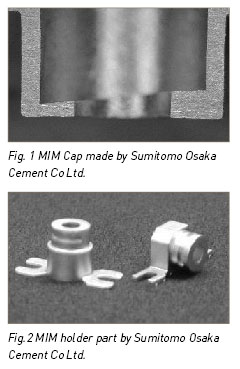

Examples of MIM parts in this area include the shown cap part (Fig.1) with thickness varying from 0.1 mm to 0.2 mm – this part would be difficult using conventional pressing because of the angled bottom. Also shown (Fig.2) are holder parts with flange where the flange was previously welded to the holder. Another example is a box shaped packaging part, made from Kovar, Fe-50%Ni, with tolerance within ±0.5% and 304L stainless steel ferrules offering good weldability.