Meta Additive awarded Innovate UK SMART Grant for BJT process

February 4, 2021

Meta Additive, Stoke-on-Trent, Staffordshire, UK, reports it has recently been awarded the lead partner role in a £1.2M Innovate UK SMART grant entitled ‘Hierarchical Binderjet Printing Process.’ The project began in November 2020 and will run for two years, aiming to develop new functional binder formulations with high solid metal loadings, using EpiValence raw materials to achieve metal Additive Manufacturing of multi-materials.

Partners in collaboration include the UK’s Manufacturing Technology Centre (MTC), Coventry, West Midlands; EpiValence, Redcar & Cleveland, North Yorkshire; and Xaar, based in Cambridge, Cambridgeshire.

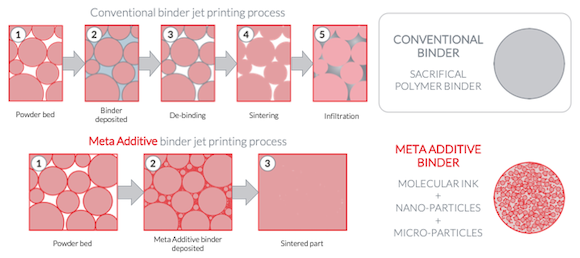

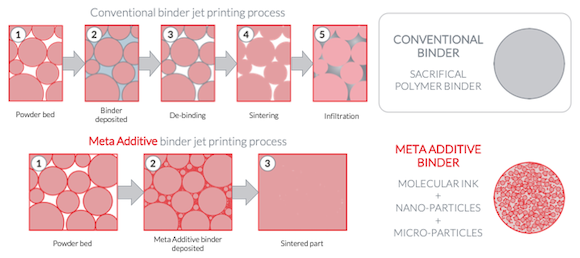

In the conventional BJT processes, a sacrificial binder is selectively deposited onto the powder bed, bonding these areas together to form a solid part one layer at a time. Meta Additive’s project team have developed and patented a new AM process which takes the benefits of standard BJT and enhances its utility to make it suitable for mass manufacturing with an aim toward filling the market’s void.

Meta Additive’s technology is said to deliver a binder that can simultaneously bind and infiltrate the pores between the powder bed, with functional build material, hierarchical binders, in place of a sacrificial binder.

The team at Meta Additive will utilise multi-scale computational modelling of hierarchical binder systems to inform novel formulations and industrial process modelling of sintering profiles. From there, Binder Jetting will be utilised in the design and development using commercially available inkjet heads, to develop BJT at scale.