Markforged completes Digital Metal acquisition

August 31, 2022

Markforged, Watertown, Massachusetts, USA, has announced that it has successfully completed the acquisition of Digital Metal from Höganäs AB, Sweden, for around $32 million in cash, 4.1 million shares of Markforged common stock and approximately $1.5 million in cash to settle intercompany balances. Digital Metal, and its team of professionals, will continue to operate under the Digital Metal brand as a subsidiary of Markforged.

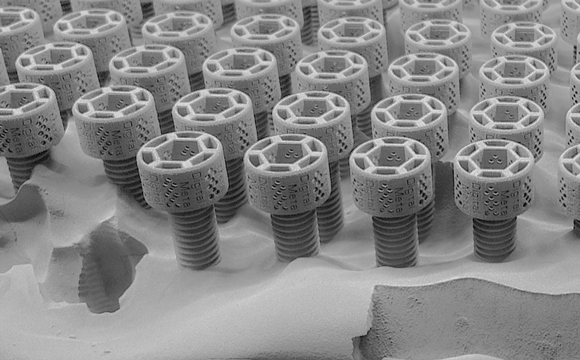

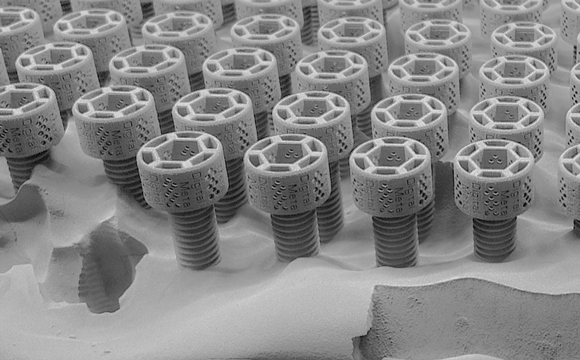

Digital Metal’s proprietary Binder Jetting technology is reported to enable the production of highly complex, precision metal components with superior surface finish, part quality and reliability. The company’s BJT capabilities for production grade parts enable manufacturers to produce high volumes of functional metal parts from a variety of metals, including stainless steels, titanium and copper.

“We are excited to successfully complete the acquisition of Digital Metal, and officially welcome its team to Markforged,” stated Shai Terem, president and CEO of Markforged. “Together, we will continue advancing our vision for distributed manufacturing by bringing the high volume production of precise metal parts directly to the point of need. By integrating Markforged’s software capabilities and global go-to-market engine with Digital Metal’s precise and reliable Binder Jetting solution, we expect to unlock significant opportunities to further accelerate Digital Metal adoption into our existing and future customers.”