Desktop Metal qualifies 420 stainless steel for its Production System

October 22, 2021

Desktop Metal, Inc., Boston, Massachusetts, USA, has qualified 420 stainless steel for use on the Production SystemTM platform, which leverages its patent pending Single Pass JettingTM (SPJ) Binder Jetting (BJT) technology.

A martensitic heat-treatable stainless steel, 420 stainless steel is characterised by its high strength and hardness, as well as its corrosion resistance when exposed to the atmosphere, foods, fresh water, and mild acids when in a fully hardened condition. It is a common material used extensively across a variety of applications such as surgical and dental instruments, ball bearings, gear shafts, pump and valve components, fasteners, gauges, hand tools, and high-end cutlery.

“Engineers continue to seek out metal Additive Manufacturing as a leading option to drive innovation in design and manufacturing,” stated Jonah Myerberg, CTO and co-founder of Desktop Metal. “We believe our qualification of 420 SS and other high-strength alloys will accelerate the deployment of our AM 2.0 solutions among customers looking to successfully mass-produce critical parts at scale.”

The company’s materials science team has qualified and fully characterised 420 stainless steel additively manufactured on the Production System, and found that it meets MPIF 35 standards for structural Powder Metallurgy parts set by the Metal Powder Industries Federation (MPIF). Producing 420 stainless steel parts on the Production System platform eliminates the use of tooling and minimises material waste, as well offering shorter production times and part cost compared to conventional manufacturing methods.

Key application use cases include:

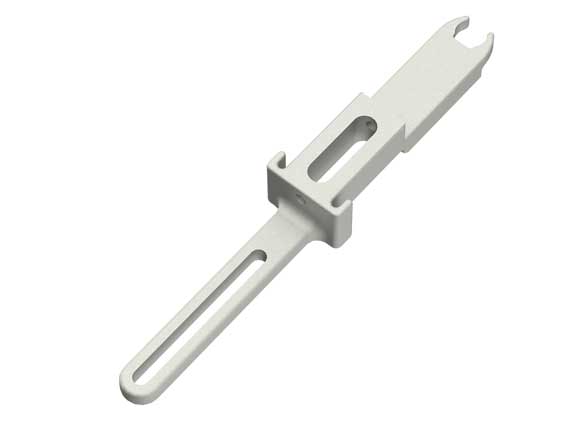

Medical/surgical: Locking articulation bar

Robotic surgical systems used in a variety of medical procedures provide surgeons with a better range of motion, enhanced visibility, and a level of precision unachievable with manual surgeries. These systems feature highly precise motion systems with many small intricate parts.

For components like locking articulation bars, 420 stainless steel is a desired material for its high hardness and excellent corrosion resistance. Since no tooling is required to produce these parts with the Production System, volume production can begin as soon as the design is complete, saving time and money on large non-recurring costs of tooling design and fabrication.

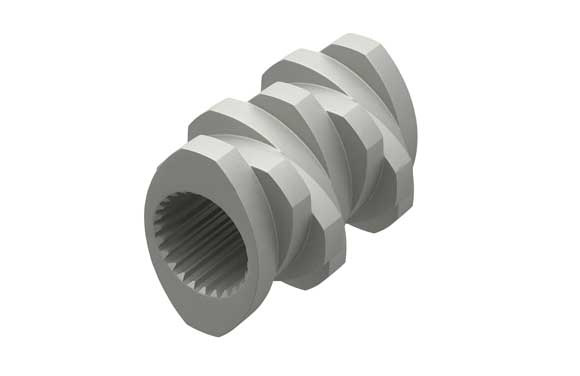

Aerospace: Valve nozzle adapter

Valve nozzle adapters connect nozzles with fluid systems in aerospace applications, where multiple versions of these adapters are often required to accommodate various nozzle geometries and sizes. Engineers prefer 420 stainless steel for this type of adapter because of its excellent corrosion resistance and high hardness.

With capacity for thousands of adapters in a single build, the Production System can support the manufacturing of these components in 420 stainless steel in volumes competitive with conventional manufacturing methods. In addition, with no tooling required, numerous adapter geometries can be additively manufactured within a single build, saving lead time and costs associated with changing over tooling in conventional manufacturing processes.

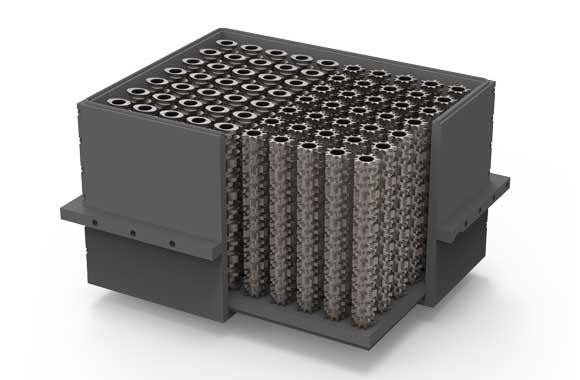

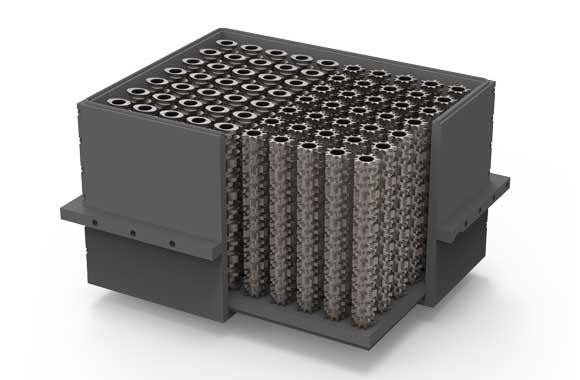

High-volume manufacturing: Twin screw extruder mixing elements

Twin-screw extruder mixing elements are used for mixing, compounding and processing viscous materials. These parts feature complex lobes around the exterior of the spline that must be optimised for the material being extruded, necessitating a unique mixing element for each different material. With conventional manufacturing, each of these elements can be complex to produce, often requiring advanced machining techniques, multiple machining setups, and custom fixturing.

Binder Jetting with the Production System simplifies the manufacturing process, enabling large volumes of several unique mixing elements to be additively manufactured in each build, reducing the cost and lead time of production compared to machining. 420 stainless steel is an essential material in these applications for its high hardness and corrosion resistance, ensuring the elements have a long lifetime and the hardness required for extruding a wide variety of materials.