Ceramic Injection Moulding used to produce microfluidic chips

October 17, 2022

Microfluidic devices have gained tremendous interest in both academic and industrial research due to key advantages such as fast response times and low analytic consumption. The manufacture of first generation microfluidic chips involved silicon but, to date, numerous materials (e.g., quartz/fused silica, glass, ceramics, polymers and metals) have been used depending on the diverse functionalities of the various microfluidic devices.

Currently, some microfluidic applications are integrated with infrared (IR) spectroscopy, which is used to measure the bond vibration frequency in a molecule and determine the functional group. Most polymeric and glassy substrates used in microfluidics chips are, however, not transparent in the mid-infrared region, and normal IR-compatible materials are expensive and challenging for micro-fabrication. Transparent polycrystalline ceramics can solve the problems of transparency and have the potential to be used in microfluidics applications coupled with FTIR analysis, providing that the required micro-features can be manufactured in the ceramic substrates at low cost.

A joint research programme at the Singapore Institute of Manufacturing Technology (SIMTech), School of Mechanical and Aerospace Engineering, Nanyang Technological University (NTU), and the Institute of Chemical and Engineering Science (ICES), all based in Singapore, has shown that Ceramic Injection Moulding can successfully be used to produce net or near-net shape high performance IR transparent ceramic microchips with small complex micro features as fine as 100 µm at a relatively low cost. The results of the research outlining the feasibility to produce IR transparent ceramic microfluidic chips with the desired feature profiles, microstructures and optical properties by PIM have been published as a Short Communication by Tao Li, et al., in Research & Development in Materials Science, July 7, 2021, 1707-1712.

The authors of the communication reported that high-purity yttria (Y2O3) powder having an average particle size of 0.25 µm was spray dried to produce spherical particles of 30–50 µm. 5 mol.%3Y-zirconia powder was added to batches of the yttria powder by ball milling in order to reduce the sintering temperature and further improve transparency. To this mixture was then added an in-house developed binder system based on paraffin wax (PW), polypropylene (PP) and stearic acid (SA) to produce the CIM feedstock.

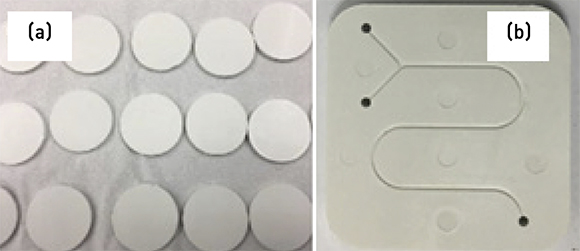

After optimising the injection moulding parameters, circular discs of 20 x 2 mm and square microfluidic chips of 25 x 25 x 2.5 mm with micro-channels of 200 µm width and depth of 100 µm were produced as shown in Fig. 1. Solvent debinding was used to remove most of the PW and SA binders from the moulded green parts. The remaining binder was removed in a multi-stage thermal debinding process, in which the parts were heated up in an inert atmosphere and strictly controlled heating profile. After thermal debinding, the brown parts were transferred to a high vacuum furnace for sintering at temperature of 1770°C and different dwell times.

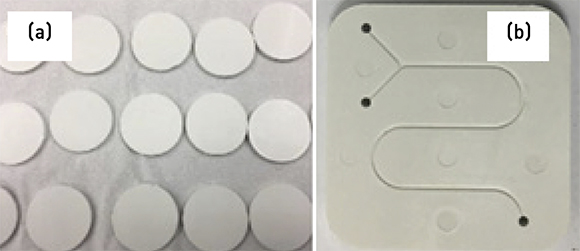

As mentioned earlier, the addition of zirconia plays an important role in manufacturing transparent yttria. PIM discs with and without zirconia sintered at 1750°C are shown in Fig. 2 and it is clear that the as-sintered sample without zirconia addition (Fig. 2a) is still opaque whilst a certain transparency has been achieved with zirconia addition (Fig. 2b).

Polishing the yttria disc sample containing zirconia gives an even better transparency compared with the as-sintered part (Fig. 3). Light transmittance in the polished PIM discs is also increased by around 10–20% compared with the unpolished samples. The researchers stated that this is due to less light being scattered at the polished surface compared to that of the unpolished surface. For the parts after polishing, the transmittance is around 50—70% in the visible light range (400—800 nm). The transmittances increase from short wavelength to long wavelength and the sample has a transmittance of 70—74% at the infrared wavelength. Compared with yttria single crystal, which has a transmittance around 80% in the same wavelength range, 90% of transmittance can be achieved in the polycrystalline ceramic produced by Powder Injection Moulding.

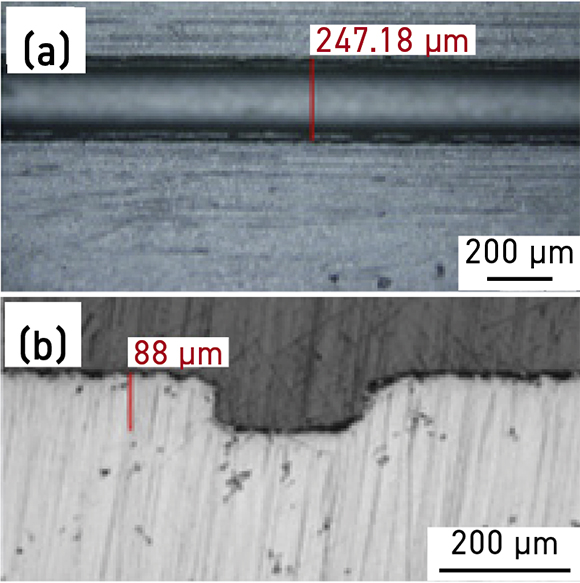

The micro-channels in the sintered ceramic microfluidic chips were found not to dramatically affect transparency. Fig. 4 shows the top view and cross section of the channel under optical microscope with width of around 250 µm and depth of around 90 µm.