Bosch Advanced Ceramics reveals additively manufactured microreactor

July 14, 2022

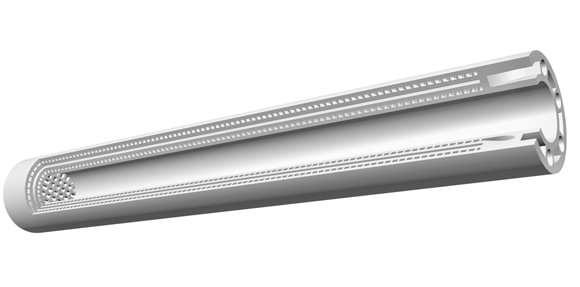

Bosch, together with the Karlsruhe Institute of Technology (KIT) and BASF, Ludwigshafen, Germany, have successfully produced what is claimed to be the first additively manufactured microreactor made of technical ceramics.

Microreactors are devices for housing chemical reactions. In terms of heat, stability and corrosion, few materials can withstand the extreme conditions caused by high-temperature chemical reactions. “To control and monitor a chemical reaction, a reactor needs to have hardness, heat resistance, and complex structures inside,” stated Klaus Prosiegel, sales manager at the Bosch startup Advanced Ceramics, based in southern Germany. “3D printed technical ceramics bring these excellent properties to the table.”

Bosch Advanced Ceramics was aware that technical ceramics are well suited for chemical reactions. “The challenge, however, lay in producing complex structures within the ceramic reactor,” Prosiegel added. To solve this problem, the startup’s ten-strong team combined their company’s two core competencies of technical ceramics and Additive Manufacturing. “We’ve successfully employed 3D printing to produce ceramic components that can’t be made by conventional means,” he said.

BASF is now using this microreactor in basic research, since it allows the monitoring of chemical reactions under ideal temperature conditions. Furthermore, it requires fewer raw materials and less energy than large reactors. Experts can analyse these small-scale results and extrapolate them for large-scale implementation.

The next phase will be to additively manufacture a further ten to twenty reactors of the same design for BASF. In view of the potential applications for technical ceramics in the chemicals sector, Prosiegel sees a bright future, “After all, almost every laboratory crucible is made of technical ceramics,” he added.