Analysis of Additive Manufacturing materials from Wohlers and Senvol Database

March 30, 2020

Data from its Senvol Database, compiled by Senvol, New York City, USA, was used to provide an historical analysis of Additive Manufacturing materials in Wohlers Report 2020. The annual Wohlers Report, now in its 25th edition, provides a worldwide review and analysis of the global Additive Manufacturing industry.

Recognised as one of the leading industry reports on AM, the 380-page report is available in both digital and print, and includes forty-two charts and graphs, 168 tables and 377 images and illustrations. The Senvol Database is free to use via Senvol’s website; the data within is available for license and can be integrated into any type of AM software.

Together, Senvol and Wohlers Associates have decided to make their historical analysis of AM materials publicly available. The excerpted analysis, as published in Wohlers Report 2020, is provided below.

Materials Database

Senvol maintains a public database of AM systems and materials, known as the Senvol Database. Specifically, Senvol tracks producers of materials and the products they offer. For example, if a company offers five grades of stainless steel powder for AM, each in four particle-size distributions, the database counts them as twenty individual material products. This data can be investigated at senvol.com/material-search. It has been filtered to omit discontinued products as of March 2020.

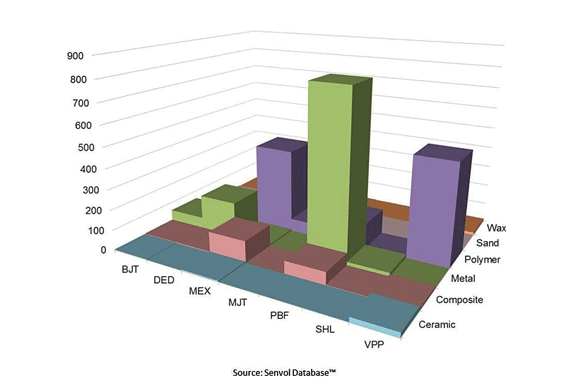

Materials by process

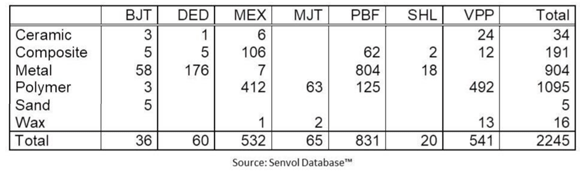

The following chart shows the number of material products for each of the seven major AM processes and six types of materials. The data was pulled from the database in early March 2020. Some metal powders are available for multiple processes, such as Powder Bed Fusion (PBF), Directed Energy Deposition (DED), and Binder Jet (BJT), and were counted separately for each process.

The most diverse materials offering is for metal PBF by a large margin, followed by Polymer Vat Photopolymerisation (VPP) and Material Extrusion (MEX), respectively. The data is tabulated as follows. Note that MJT stands for material jetting and SHL stands for sheet lamination.

Materials producers and products

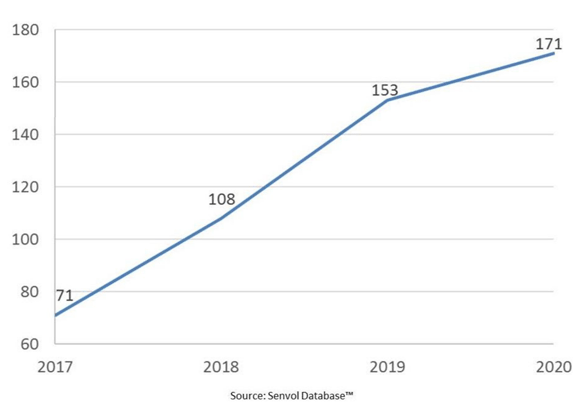

Senvol tracks the companies that supply AM materials. They include AM system manufacturers and producers of third-party materials. The total number of suppliers is listed by year in the following graph. All data used to produce the following charts is from March of each year.

The number of material suppliers more than doubled from 2017 to 2019, though growth slowed slightly in 2020.

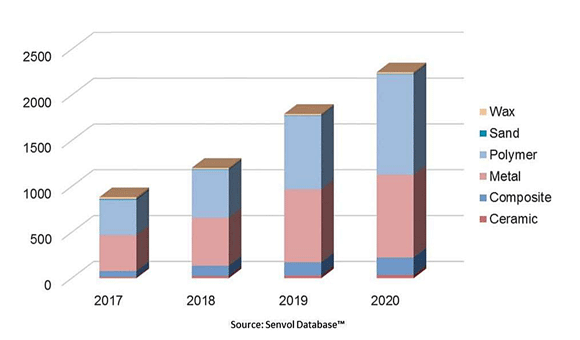

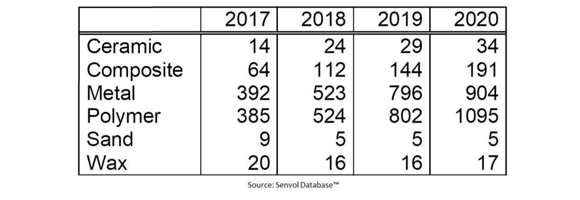

The following chart shows the number of commercially available material products by type:

Most AM materials are polymers and metals, with composites growing into a notable portion. Ceramics, sand and wax represent specialised applications and systems, and are only available from a narrow selection of suppliers. The following shows this data in tabulated form:

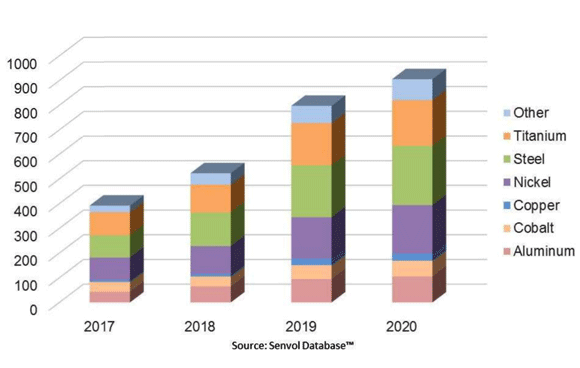

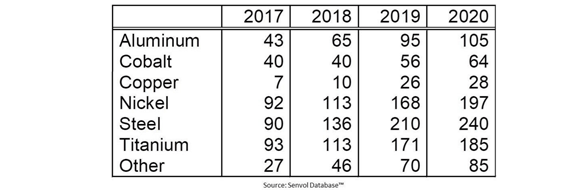

The following chart shows metal products available for AM for the past four years. They include filaments, powders, sheets, and wire stock for metal AM processes:

Nickel, steel, and titanium products have led the metals market by a large margin, although aluminium products are growing. The ‘Other’ category includes iron, precious metals and refractory metals. Applications for these metals are increasing, but the materials are available from a limited number of suppliers. Corresponding data from the previous chart is presented in the following table.

The Senvol Database is free to use on Senvol’s website. Furthermore, the data within the Senvol Database is available for license and can be integrated into any type of AM software.

More information, including the properties of AM materials, is available from the Senvol Database. The database can be used to find equipment and materials using many fields, such as machine build size, material type, AM process type, and material tensile strength.