PIM International, Vol. 1 No. 4 December 2007

Print copies of this issue are however still available to purchase for £35.00 including free shipping worldwide.

To order a print copy please email [email protected].

Demand for precision components set to drive Chinese powder injection moulding manufacturing into the mainstream

In this specially commissioned feature for Powder Injection Moulding International Prof. Dr. Yimin Li of the Powder Metallurgy Research Institute, Central South University, Changsa, China, presents an insight into current PIM production in China and identifies the markets and applications that are driving the technology forward.

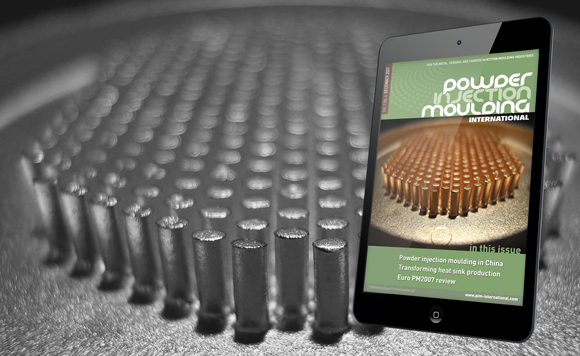

Metal Injection Moulding technology set to transform the design and production of heat sinks

Rapid developments in microprocessor technology have led to a need for the efficient high-volume production of advanced heat sink devices. As Lye-King Tan of Acelent Technologies Pte Ltd explains, the metal injection moulding process is highly suited to the production of the next generation of these high performance products. metal injection moulding offers product designers a greater freedom to adapt traditional heat sink designs to offer both increased thermal efficiency and substantial cost savings in high volume production.

GKN: Global powder metallurgy leader GKN Sinter Metals optimistic as metal injection moulding gains acceptance with end-users

GKN Sinter Metals, a leading global powder metal (PM) parts supplier, opened the doors of its Bad Langensalza metal injection moulding plant to Powder Injection Moulding International. Dr. Georg Schlieper talked with Jens Wolf about his views on metal injection moulding technology and the outlook for business.

Euro PM2007 provides platform for innovations in PIM

The Euro PM2007 Congress and Exhibition, organised by the European Powder Metallurgy Association (EPMA) in the aerospace city of Toulouse, southern France, from October 14-17, proved to be an excellent venue for this growing annual meeting of the PM industry and its suppliers. Powder Injection Moulding International reports for on the event highlights.

MIM workshop focuses on component design

A half-day ‘Special Workshop’ was held during Euro PM2007, Toulouse, which had the objective of giving delegates an insight into design optimisation for metal injection moulding (MIM) through analysis of parts already in production, and specific case studies which illustrated design solutions achieved by metal injection moulding in automotive and power tool applications. Powder Injection Moulding International reports on some of the presentations given.

Euro PM2007 technical presentations highlight the possibilities and advantages of PIM

The technical sessions at Euro PM2007, Toulouse, provided an insight into current directions for both PIM research and development and industrial production. Powder Injection Moulding International reports on three highlights from the conference sessions.

Laminar gas flow presents new opportunities for efficient debinding and sintering

Claus J. Joens (Elnik Systems) and Satyajit Banerjee (DSH Technologies, LLC) look at the benefits of laminar gas flow in batch furnaces. Laminar gas flow can offer many advantages for the metal injection moulded part producer. As well as offering a great degree of versatility and flexibility in producing a wide variety of metal injection moulded parts, the technology eliminates the need for a separate thermal debinding step.

Al/SiC composites with high reinforcement content prepared by PIM/pressure infiltration

Xiangquan Liu, Yimin Li, Fenghua Luo and Meiling Li

The preparation and thermo-physical properties of Al/SiC composites with high reinforcement content (65vol%) were investigated. In order to obtain the feedstock with a high powder loading, SiC mixtures containing fine and coarse powders were investigated to obtain the optimal particle packing.

Research on the metal injection moulding of housings for the semiconductor industry

Zhang Chi, Xu Bo and Wu Ziguang

The process of metal injection moulding (MIM) for a semiconductor housing is analysed in this paper. With an introduction of a new type of binder system for processing Fe-Ni alloy based housing parts using MIM process, the efficiency of the debinding process is greatly improved. In addition, the sintering process is stabilised.

Qualification of material DIN 1.4404 (316 L) for liquid hydrogen storage applications

Rudolf Zauner and Michael Scheerer

316 L (DIN1.4404) is known to be the most commonly used material in metal injection moulding. In search for new applications for MIM, the material DIN 1.4404 has been tested for its mechanical properties under liquid hydrogen conditions (-253°C). Tensile bars and impact strength test bars were injection moulded and sintered.

Browse our PDF archive by year

The following years of Powder Injection Moulding International magazine are available to download in PDF format, free of charge, from our archive.