Volume Graphics releases new CT software solutions for non-destructive testing

July 12, 2019

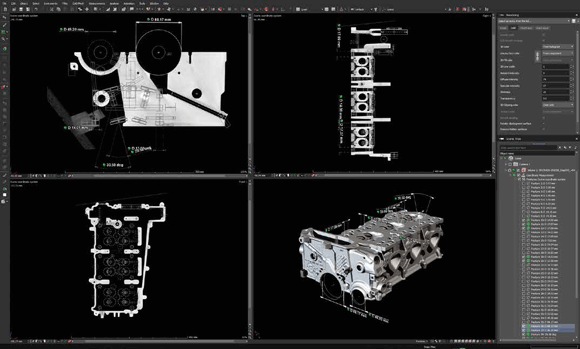

Volume Graphics’ VGStudio Max software for CT inspection (Courtesy Volume Graphics)

Volume Graphics GmbH, headquartered in Heidelberg, Germany, has released version 3.3 of its software solutions for non-destructive quality assurance with industrial computed tomography (CT): VGStudio Max, VGSTudio, VGMetrology, and VGInLine. Volume Graphics’ VGStudio Max software is used for the analysis and visualisation of industrial CT data and is said to cover all requirements related to metrology, defect detection and assessment, material properties, and simulation.

Using the new version, customers can reportedly determine the surfaces of multi-material components, export measurement and analysis results to store them centrally in quality-management software, automate inspection processes more flexibly based on text recognition, and translate real CT data into volume meshes for simulation. To further support its customers, Volume Graphics has also added a new Technical Consulting unit that provides professional consulting and evaluation services.

“With version 3.3 of our software solutions, we are once again laying the foundation for customers to make their processes smarter,” stated Christof Reinhart, CEO and co-founder of Volume Graphics GmbH. “For example, using the new data export, metrology data derived with the tremendous measurement capabilities of our software can be seamlessly shared with QA systems, where the values can then be combined and checked over time.”

“More than ever before, this new feature enables customers to better integrate leading-edge CT technology into their existing software landscape,” he continued. “The new export feature is based on the native support of the widely used Q-DAS format, which makes using results in third-party statistical or analysis software especially easy.”

Volume Graphics GmbH has been developing software for non-destructive testing based on industrial CT for over twenty years, and is said to have a market share of around 80%. Its software is used widely for quality assurance in product development and production by customers in the automotive, aerospace, and electronics industries.