Metal Injection Moulding of magnesium alloy WE43 for biomedical applications

April 15, 2024

Magnesium alloy WE43 is a high-strength, lightweight alloy developed in the 1980s containing rare earth (RE) elements including: yttrium (Y), neodymium (Nd) and gadolinium (Gd). The relatively-high solubility, the small difference in electrode potentials, and the passivation effect of the RE elements in the WE43 alloy considerably improve its resistance to oxidation and corrosion, making this alloy one of the few biodegradable metals that have achieved clinical applications.

However, whilst conventional manufacturing processes such as casting and extrusion have been used to produce regular shaped components from WE43 for biomedical applications, they are often not economic for customised, patient-specific, complex shapes having the required strength, ductility and corrosion properties. Here binder-based processes such as Metal Injection Moulding, and also sinter-based Additive Manufacturing (AM), have been shown to have the potential to produce complex near net-shape parts such as biodegradable WE43 alloy bone screws, vascular stents and surgical implants in high numbers and with high reproducibility.

Researchers at the Helmholtz-Zentrum Hereon GmbH, Geesthacht, Germany, and the Christian Albrechts University in Kiel, Germany, have been focusing on the use of MIM to produce Mg WE43 alloy components for biomedical applications, and the results of their work have been published in a paper by M Wolff, E Nidadavolu, W Limberg, T Ebel, and R Willumeit-Römer in Key Engineering Materials Vol. 967, December 12, 2023, pp 157-164.

The authors of the paper believe that this was the first time MIM has been used to produce components from the Mg WE43 alloy and, from their published results, it was shown that sufficient strength and elongation at fracture could be obtained using the MIM process.

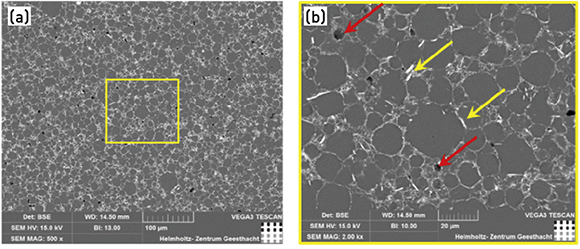

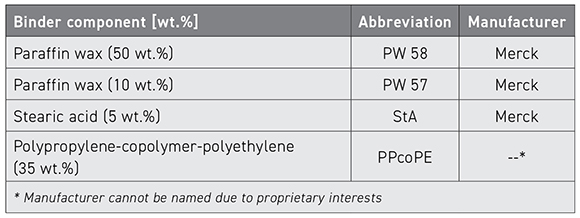

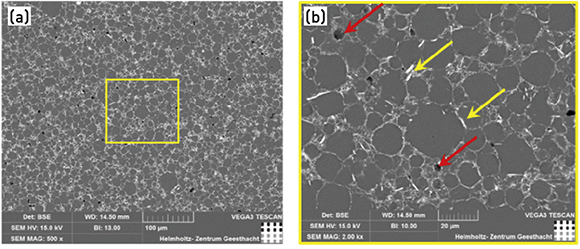

The feedstock was based on a gas atomised spherical magnesium WE43 alloy powder having particle size below 45 µm, which was mixed with different binder components as shown in Table 1. Mixing was done under protective inert gas atmosphere (argon) to prevent any oxygen uptake in the feedstock. The Mg WE43 alloy feedstock was then injection moulded to produce green dogbone tensile test specimens. The green parts were solvent debound in hexane at 45°C for 900 min to remove the wax binder and stearic acid, leaving only the proprietary PPcoPE polymer as the backbone binder in the brown parts to retain their shape during thermal debinding and sintering. The PPcoPE binder was removed in a combined thermal debinding and sintering furnace using a separate binder precipitation zone. Final sintering was done under high purity argon at 640°C for 64 h. The residual porosity of the as-sintered WE43 material was 1.3% ± 0.1%.

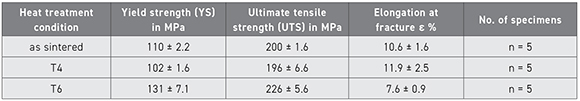

The sintered MIM Mg WE43 alloy parts were then subject to solid solution heat treatment (T4) at 540°C for 26 h, followed by precipitation sinter-hardening heat treatment (T6) at 227°C for 32 h. The mechanical properties of the Mg- WE43 material in the as-sintered, T4 and T6 heat treated condition, are shown in Table 2. With additional T4 and T6 heat treatment after sintering, the MIM Mg WE43 alloy could achieve enhanced material properties with ultimate tensile strength (UTS) of 226 MPa at 7.6% elongation at fracture. This compares with 250 MPa UTS, 160 MPa YS and only 2% elongation in T6 chill cast WE43 alloy.

The authors found that diffusion of the yttrium, gadolinium and neodymium alloying elements in the magnesium matrix of the as-sintered MIM WE43 material during T4-solid solution heat treatment could not be performed satisfactorily, leading to slightly lower mechanical properties but increased elongation. This might be due to the oxide layer hindering the diffusion of the alloying elements into the α Mg-matrix within the given time for T4 heat treatment. The incomplete T4 heat treatment showed that T6 precipitation hardening could not then be fully performed and that the final WE43 microstructure still contained coarse secondary phases as shown in the SEM images in Fig. 1(a) and Fig. 1(b). Nevertheless, mechanical tensile testing of the MIM WE43 alloy still proved the overall beneficial effect of T4 and T6 heat treatment on the UTS, YS and elongation results shown in Table 2.

The authors plan to carry out further investigations into the question of inhibited solid solution ability of the alloying elements yttrium and gadolinium during T4 heat treatment, and will also investigate the introduction of the magnesium WE43 alloy powder for sinter-based Additive Manufacturing.

Download PIM International magazine