SSI and ExOne to accelerate volume production in metal Binder Jetting

September 23, 2021

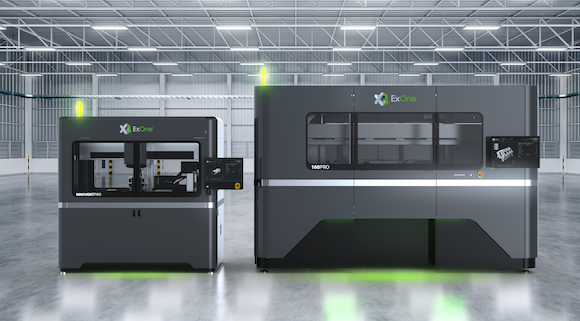

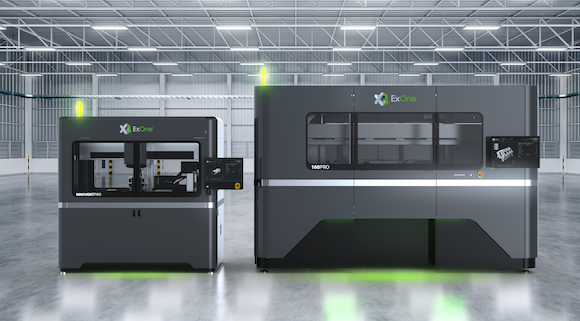

SSI Sintered Specialties, headquartered in Janesville, Wisconsin, USA, has announced its purchase of an X1 160Pro and InnoventPro 3L metal Binder Jetting (BJT) Additive Manufacturing machines from The ExOne Company, North Huntingdon, Pennsylvania, USA. The two machines are slated for delivery in the first half of 2022 and will be located at the company’s headquarters.

“The addition of metal Binder Jetting to SSI’s technology portfolio was the natural next step in providing our customers with the most advanced technology on the market to produce complex geometries in volume production,” stated Paul Hauck, COO, SSI Sintered Specialties. “Our expertise and lengthy heritage in high-temperature metallurgy processing is a perfect fit for Binder Jetting technology, and we are thrilled to be working with ExOne to offer our customers the future of metal 3D printing.”

SSI has over forty years of Powder Metallurgy experience, and metal Additive Manufacturing adds to the company’s existing capabilities in press & sinter PM and Metal Injection Moulding (MIM). With ExOne’s AM machines, the parts manufacturer intends to offer components with increased complexity and size for volume production without the need for tooling in a variety of metals. The investment in ExOne’s BJT technology is said to be just one of the steps in SSI’s business strategy to embrace AM and bring new manufacturing solutions for volume production.

In addition to serving customers, SSI and ExOne will now be collaborating in a variety of BJT material, automation, and process areas. SSI will use the InnoventPro for material and application development, with the 160Pro dedicated to volume production through a fully automated cell with continuous sintering and furnace equipment. To date, ExOne has qualified more than twenty materials for its BJT process, including twelve metals, five composites and four ceramics. Aside from stainless and tool steels such as 17-4PH, 316L, M2 and H13, ExOne has qualified Inconel 625, aluminium 6061, copper and more.

The InnoventPro 3L, which features a build area of 220 x 125 x 100 mm, is said to be the world’s most advanced metal BJT system, with the capability to use ExOne’s NanoFuse™ particulate binders. The X1 160Pro is reported to be the world’s largest metal BJT system, with a build area of 800 x 500 x 400 mm, and offers the most qualified materials available. The two systems use the same printheads, so customers can scale their R&D on the InnoventPro to production with the 160Pro.

“ExOne is delighted to have our cutting-edge binder jet technology adopted by such an experienced powder metallurgy partner and high-quality parts supplier such as SSI,” added John Hartner, CEO, ExOne “We look forward to driving Binder Jetting to full production for a wide range of customers who will now be able to unlock new value with innovative new designs that were once impossible or too expensive to produce with traditional manufacturing.”