Sandvik Osprey expansion reflects a positive outlook for MIM

March 2, 2007

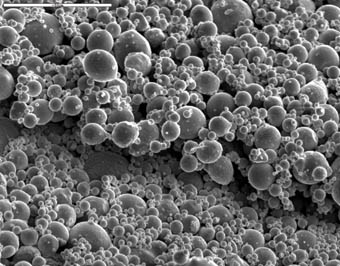

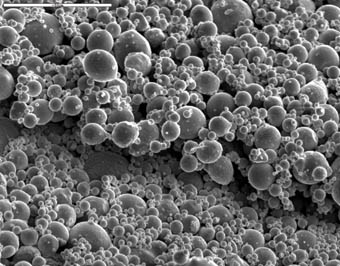

The growing acceptance of MIM as a maturing manufacturing technology is reflected in increasing demand for MIM powders. Sandvik Osprey Ltd, a leading supplier of gas atomised powders for MIM worldwide, has supplied the industry over 15 years with fine MIM powders in a wide variety of compositions and customised size ranges.

The company’s commitment to the sector and its customers has recently been reinforced by a major new $2 million investment, completed at the end of 2006 at its powder production plant in Neath, UK.

The investment provides a large scale production unit and radically improved infrastructure which will enhance the company’s cost base and flexibility. The new facility is the company’s fifth atomising unit at the Neath site which will more than double its production capacity for a wide range of alloy powders from development quantities through to high volume production.

As the company’s Managing Director Richard Park points out: ‘This new plant means that we can now respond to large scale enquiries for high volume applications where cost is particularly critical. It also enables us to improve our cost base and product characteristics which will benefit our customers’.

The boundaries for MIM applications are expanding from small, complex parts in simple alloys to embrace larger and relatively simple parts in a wide variety of alloys for high volume manufacture. Against this background, capacity and a competitive cost base are critical for customers to compete with other high volume manufacturing routes such as forging, machining and investment casting. Moreover high quality powders which give consistent properties are becoming more critical. In this respect, the low oxygen contents achievable with gas atomised powders and master alloys which enable excellent sintered properties and low distortion on sintering, are advantageous. The new investment signals Sandvik AB’s commitment to powder metallurgy.

For more information visit www.smt.sandvik.com