Researchers detail Additive Manufacturing method for unsupported ceramic structures

June 29, 2023

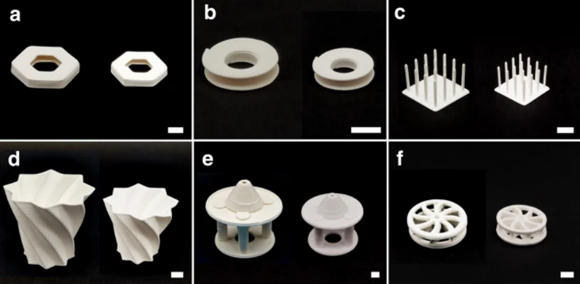

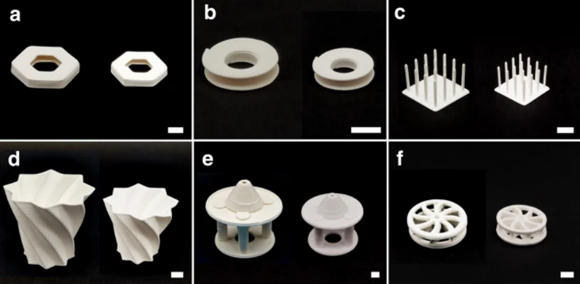

Researchers from Jiangnan University, Jiangsu, China, recently published an article in Nature Communications investigating a new method of ceramic Additive Manufacturing which can realise the manufacture of unsupported multi-scale and large-span ceramics.

The method was reportedly made possible through the combination of direct ink writing and near-infrared (NIR) induced up-conversion particles-assisted photopolymerisation enabling the in-situ curing of multi-scale filaments with diameters ranging from 410 µm to 3.50 mm. Ceramic structures of torsion spring, three-dimensional bending and cantilever beam were successfully constructed through unsupported Additive Manufacturing.

On-demand curing using NIR irradiation at a controlled curing rate can reportedly obtain ceramic structures with flexible geometries and characteristic dimensions via this new method. Adjusting the irradiation intensity and build speed allows the ceramic slurry to be cured in-situ during extrusion without the use of supports. The article states that this improves manufacturing precision and that the flexibility of Additive Manufacturing extends to the X-Y-Z space, which reportedly makes it easier to additively manufacture low-angle or horizontal overhangs without defects.

The full paper ‘3D printing of unsupported multi-scale and large-span ceramic via near-infrared assisted direct ink writing’ is available here.

Download PIM International magazine