MPP’s Metal Injection Molding provides the solution for dynamic braille reader

April 29, 2024

MPP, headquartered in Noblesville, Indiana, USA, has collaborated with Tactile Engineering, an Indiana-based startup developing advanced assistive technologies, to help design a metal injection molded core plate for Tactile’s Cadence tablet, a groundbreaking braille reader for the visually impaired.

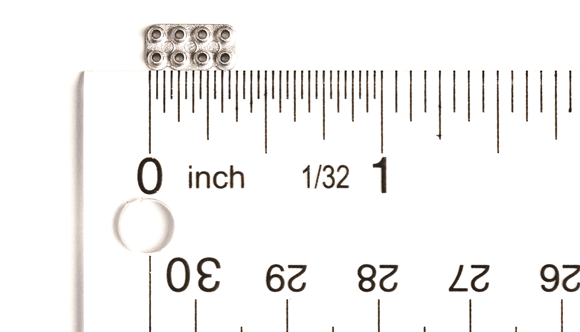

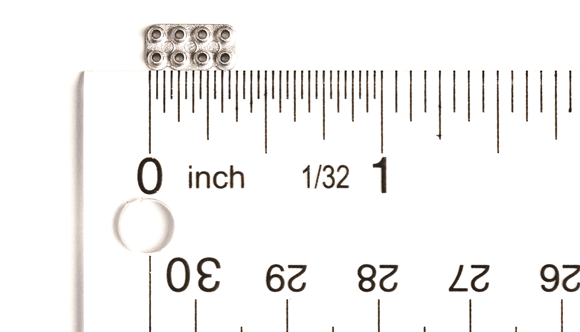

The Cadence tablet is reported to be the first tactile device able to display tactile graphics that move and change beneath the user’s fingers. The pocket-sized tablet, around the size of a large mobile phone, enables users to interact and experience live events and entertainment, as well as provide access to dynamic content, textbooks, and collaborative tools.

The innovative tablet also helps students of all ages learn and use braille. The tablet’s pop-up dots provide just the right amount of resistance for comfortable and easy reading, with up to eight lines of text for quick navigation of long passages and complex information.

The new MIM core plate was designed to meet tight tolerances, requiring flatness, the absence of any flashing, and specific magnetic properties, essential for the tablets functionality. If the part was not produced within the precise specifications, it would run a risk of creating a short and the inability to function.

With that in mind, MPP used 17-4 Stainless Steel, as per MPIF Standard 35, for the magnetic latching. Utilising a proprietary feedstock formulation, MPP was also able to ensure material flow through the molding.

Transitioning to Metal Injection Molding from traditional manufacturing methods led to a 40% reduction in waste and a 10X cost saving per piece. The MIM solution simplified the manufacturing process and improved assembly efficiency, allowing Tactile Engineering to commit to larger volumes for their customers.

Download PIM International magazine