Research progress points to the potential of Low-Pressure Powder Injection Moulding

April 14, 2023

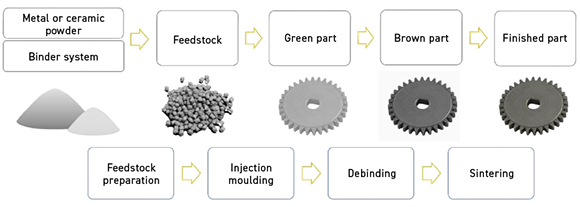

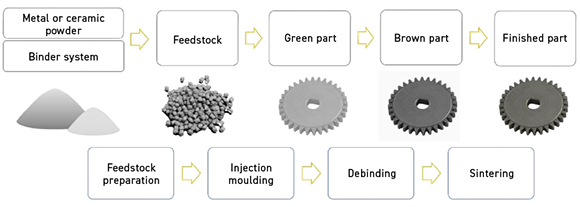

Low-pressure Powder Injection Moulding (LPIM) and High-pressure Powder Injection Moulding (HPIM) are essentially similar manufacturing processes. However, the LPIM process requires the use of low-viscosity feedstocks between 1.5 and 4.0 Pa·sec to take advantage of lower injection pressures of less than 1 MPa. HPIM injection pressures typically range between 20 and 200 MPa, using, for example, a moulding machine with a complex hydraulic unit, pistons, and spindles to process feedstocks with viscosities ranging between 100 and 1000 Pa·sec.

LPIM moulding machines, in contrast, tend to use simple hydraulic mechanisms and are generally smaller in size, resulting in lower equipment costs, lower energy consumption, lower mould wear, less feedstock contamination from spindle or piston wear, minimal mixture adhesion to the mould, and non-separation of the feedstock binder from metallic powder.

LPIM has been used successfully for ceramic component production in low and high volumes for several decades, whilst HPIM has, for the past thirty-to-forty years, focused largely on the high-volume production of a wide range of materials including alloys, hard metals, and ceramics for relatively small, highly complex shaped components. However, LPIM is attracting the attention of HPIM producers and component users because of the potential savings through using lower-cost and reduced-size injection moulding equipment, the development of feedstock binders with improved flowability using low-molecular-weight polymers, and the elimination of multiple debinding steps which are required in HPIM.

Recent research has shown that LPIM can also be a cost-effective process for prototyping and small-series production of complex, near-net shape metal-based components with high added value, such as for aerospace and medical applications. However, the primary challenge for adopting LPIM is the composition of the feedstock, which affects issues associated with injection moulding and subsequent debinding.

In order to ascertain the future potential of LPIM, a group of researchers at the Montanuniversitaet Leoben, Austria, (V Momeni, M Hufnagl, Z Shahroodi, S Schuschnigg, C Kukla and C Holzer), and the Luxembourg Institute of Science and Technology (J Gonzalez-Gutierrez), has produced a comprehensive survey of published research on the characteristics of all processing steps in LPIM, including the characteristics of metal and ceramic powders used, binders, moulding, debinding and sintering. The 44-page survey, including 226 references from both academic and industrial research work, was published online in Materials, 16, 379, December 23, 2022.

The authors of the review reported that research groups have used LPIM to produce parts from a range of metal alloys including iron, 316L stainless steel, Inconel 718 superalloy, and ceramics and cemented carbides, in the range of 100–10,000 units. Current research efforts were found to be focused on developing experimental methods and numerical simulations to examine the impact of powder characteristics, injection parameters, and feedstock properties/features on metal powder and binder segregation during LPIM.

With regard to feedstock, it was stated that the low-viscosity, multicomponent binders typically used in LPIM have largely been based on paraffin wax (PW) which ensures excellent moulding capabilities and promotes powder-binder interactions and feedstock stability, resulting in little segregation. Such low-viscosity wax-based binder systems are said to exclude polymers because of their high molecular weight.

It was stated that using higher powder loading for LPIM feedstock is usually not desirable, as it could generate process-related issues and complications such as agglomeration, inhomogeneity in the feedstock and different defects in each step. Additionally, the absence of elements in the binder that assist shape retention at high temperatures indicates the precise debinding and sintering should be performed with extra care. It can also be challenging to attain excellent mechanical characteristics with the lower powder loading in LPIM feedstock compared to HPIM feedstock.

These are just some of the challenges which have been reported on by different researchers on the LPIM process in the literature. The authors stated that this first comprehensive literature review of the many investigated metallic and ceramic materials processed by LPIM will help provide a basis for any future work required to overcome challenges.

The review is divided into six sections. Following the Introduction, Section 2 outlines the features of the ideal raw material, for both metal and ceramic, such as powder Particle Size Distribution (PSD) and its effects on surface area, rheology and packing density, all of which influence the flowability of the LPIM feedstock and the homogeneous filling of the mould cavities. This section also covers binders used for LPIM feedstock, which are composed of multiple ingredients to account for the numerous tasks the binder must accomplish. The binder must make the powder flow, prevent powder agglomeration, prevent phase separation, and decompose gradually during debinding, and should not chemically react with the powder.

In addition to focusing on the importance of suitable powder selection, numerous researchers have proposed several binder compositions that can be used with various metal and ceramic powders in the LPIM process. Ultimately, the proper combination of binder and powder in the LPIM feedstocks ensures good quality parts obtained by LPIM. As already mentioned, wax-based binders are generally used in LPIM, but the past fifteen years have seen an increasing focus on the use of low-molecular-weight polymers to produce low-viscosity feedstock.

Another successful development is a partially water-soluble binder system used for the LPIM of alumina powder. The binder system consists of Poly (2-ethyl-2-oxaline) as the water-soluble portion, LDPE for high strength during debinding, SA, and a small amount of gelling agent to decrease its viscosity. LDPE is a thermoplastic polymer used as the backbone in feedstock preparation for micro-PIM and LPIM. Iron parts have also been reported to be produced by LPIM using four irregular shaped particles sieved at < 45, <20, and <10 µm (56–58 vol.% powder loading) as well as a spherical iron powder with a d50 as low as 4 µm (62 vol.% loading) using a standard wax-based binder system.

Section 3 introduces techniques for characterising feedstocks; including rheology, thermal analysis, and several methods for determining the homogeneity of feedstocks used in LPIM.

Section 4 outlines the LPIM moulding process, which is said to be very different from HPIM, in three subsections; injection machine and mould, parameters and defects, and simulation.

Section 5 discusses debinding, which is essential due to the use of wax binders. Thermal wick debinding has been found to be highly successful for LPIM.

Section 6 describes the sintering process. The sintering step in LPIM is essentially very similar to HPIM – both are highly dependent on the metal or ceramic powder used in the feedstock. The low pressure used in LPIM can affect the sinterability of moulded and debound components and the use of sintering additives is sometimes required.

LPIM is described in this survey as a promising technology that is already in use for commercial products, with the lower cost of LPIM equipment making it a cost-effective process, whether for low- or high-volume production. A further benefit of LPIM is the ability to carry out injection moulding at lower temperatures than HPIM, which is favourable for some specific powders such as magnetic alloys vulnerable to oxidation at temperatures above 200°C.

In the final section, the authors outline their views on the further development and application of LPIM and present intriguing suggestions for future investigations with the potential to increase new opportunities for the LPIM process. They also propose the future use of LPIM feedstock in Material Extrusion (MEX)-based Additive Manufacturing processes such as ‘direct ink writing’ and ‘robocasting,’ since the feedstocks behave similarly to those used in LPIM.

www.mdpi.com/journal/materials

Download PIM International magazine