QinetiQ adds alloy powders to its nano range

October 20, 2007

QinetiQ Nanomaterials Ltd (QNL) is to commission a new small scale production plant in Farnborough, UK, in October 2007 for its range of nanopowders produced by the plasma vaporisation process – the so-called Tesima® process.

QinetiQ Nanomaterials Ltd (QNL) is to commission a new small scale production plant in Farnborough, UK, in October 2007 for its range of nanopowders produced by the plasma vaporisation process – the so-called Tesima® process.

‘The new rig will enable QNL to produce around 50g pre-production samples for evaluation and testing by customers far more quickly than was possible on its far larger Tesima® nanopowder plant capable of capacities of up to 5 tonnes/year’, stated Dr Ian Clark.

In the QNL process a feedstock material is fed into a high temperature plasma (typically in the temperature range 4,000°C to 9,000°C) which acts as a clean heat source. The feed-stock material is vaporised on contact with the plasma and is carried away from the hot zone on a gas stream.

The vapour is rapidly quenched, the material then condenses and rapidly solidifies to form nanometer sized powder particles which are carried through to a collection system. By controlling the process parameters a range of materials can be produced in a range of particle sizes. Pure metals, passivated metals (with a thin oxide layer), oxides, nitrides and other alloys and compounds can be produced.

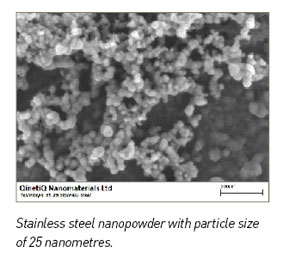

QNL recently announced the development of TesimorphTM ES-25 – an experimental magnetic stainless steel powder with a particle size of 25 nanometres. This is many times smaller than anything currently available, and is considered to be of particular interest to the MIM community where smooth flows and therefore finer detail can be achieved in micro MIM parts. The company stated that TesimorphTM ES- 25 is only the beginning of producing more complicated advanced alloy materials ranging from steels to shape memory alloys.

QNL recently announced the development of TesimorphTM ES-25 – an experimental magnetic stainless steel powder with a particle size of 25 nanometres. This is many times smaller than anything currently available, and is considered to be of particular interest to the MIM community where smooth flows and therefore finer detail can be achieved in micro MIM parts. The company stated that TesimorphTM ES- 25 is only the beginning of producing more complicated advanced alloy materials ranging from steels to shape memory alloys.