New designs for LED heat sinks by Metal Injection Moulding developed by Karlsruhe Institute of Technology

February 17, 2017

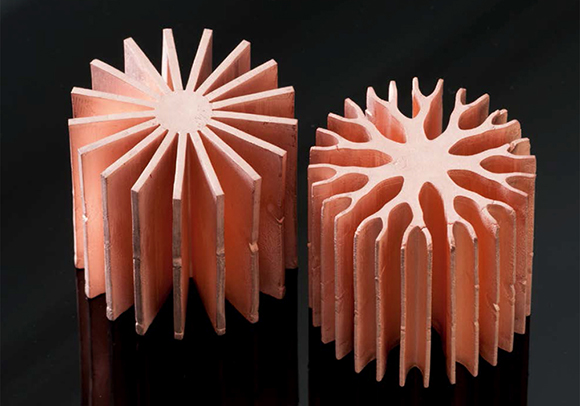

Fig. 1 Metal injection moulded copper heat sinks after sintering.

The luminous flux of LEDs decreases with the rise of the operating temperature and the dissipation of any heat generated is therefore, aside from the efficiency of the LED chip itself, an essential part of efficient LED systems. According to a recent report in LED Professional it was stated that the thermal power loss of the LED, in comparison with traditional incandescent lamps, is not radiated and therefore has to be dissipated by thermal conduction from the LED into an applied heat sink. The design of the LED heat sink has to ensure that the heat is conducted through the material to the surfaces where it is transported to the environment by convection and radiation. Thus, the design of a heat sink has to fulfil two aims: good thermal conduction in the heat sink and a design giving good thermal convection on its surfaces.

The report, prepared by Christian Herbold and Cornelius Neumann from the Light Technology Institute at the Karlsruhe Institute of Technology (KIT) in Karlsruhe, Germany, analysed nature inspired shapes that would combine high thermal performance with a high aesthetic value and which could be mass produced economically. They used Metal Injection Moulding to manufacture prototypes because of the ability of the process to produce complex shapes in large quantities and with a high level of design freedom. However, as MIM is mostly used for small parts with typical weights ranging from 1 to 100 g, the challenge was to use MIM for constructed heat sinks having two differing shapes using copper powder and weighing around 330 g, as shown in Fig. 1. The left shape reflects conventional heat sink design, whilst the right shape shows a branched design.

The authors stated that Metal Injection Moulding of such large sized heat sinks raised two problems. The size makes it difficult to fill the whole cavity with the viscous feedstock material before it solidifies in the mould and, once filled, the large surface area causes significant surface adhesion to prevent easy ejection of the moulded part. The cylindrical shape of the sample MIM heat sinks offers two advantages to deal with these problems. Because of the geometry, the whole cross-section area can be used for ejection. For this reason, the pressure to push the moulded part out of the cavity is applied to the complete cross-section area and the risk of destroying the part during ejection is reduced.

Furthermore, with this design the ejector can be used for compression moulding to support the improved filling of the cavity. However, the authors also found that by slightly reducing the degree of filling the mould could be ejected without breakage but that the moulded heat sinks then have some notches where the cavity was not completely filled.

For the MIM process, copper powder was mixed with a polymer as binder and granulated to produce the feedstock which was injection moulded on an Arburg Allrounder 570 S machine. The water soluble part of the binder in the green part was removed in a water bath followed by thermal debinding and sintering to produce the dense MIM Cu parts. During sintering the heat sinks shrink evenly to about 85% of the size of the green part.

A shape distortion caused by the shrinkage can almost be avoided with an appropriate sintering support that minimises friction between the parts and the base. The shapes in Fig. 1 represent the constructed heat sink geometries very well with the branched heat sink design based on an approximate mathematical model and several thermal simulations. These thermal simulations give the branched heat sink design an advantage of 8.4% for the given size. The notches seen in both heat sinks at half height of the MIM parts were caused by the necessary reduced degree of filling the mould. The branched MIM heat sink is 6% lighter than the non-branched type.

The researchers at KIT will carry out further work to characterise the MIM heat sinks for full heat dissipation properties. Optical measurements with LEDs will supplement the results and a comparison to standard heat sinks will be possible. They will also investigate an additional design to be manufactured by MIM with the aim of combining natural shapes with the shaping possibilities of the MIM process (Fig. 2).

Fig. 2 Possible heat sink design based on branched architecture.

They stated that heat sinks with larger diameters will extend the advance in thermal resistance, and that the beauty of the branched architecture is certainly worth thinking about for luminaires designed on this principle, combining aesthetics and performance.