MPP to relocate and expand its MIM operations, expands into AM

October 29, 2018

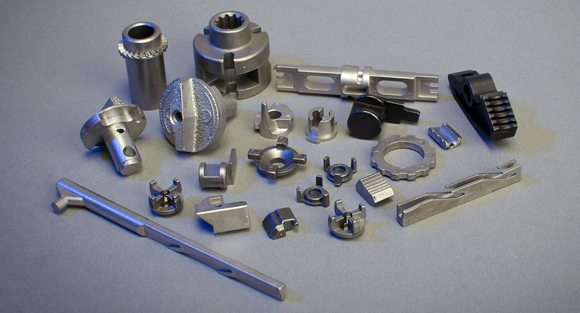

MIM parts produced for industrial and consumer applications by MPP (Courtesy MPP)

MPP, a Mill Point Capital portfolio company headquartered in Indiana, USA, will relocate its Metal Injection Moulding operations from Westfield, Indiana, to Noblesville, Indiana. Following the move, the facility will be part of the campus on which the company’s global headquarters are located.

The move is expected to allow for an expansion of current operations, with a significant increase in manufacturing capacity offered by the new 12,800 m2 (42,000 ft2) floor space, double that available at the company’s current MIM facility. The company’s technical capabilities will also be enhanced by the addition of new processing methods, and the site will also be home to MPP Additive Manufacturing.

Dennis McKeen, MPP CEO, commented, “MPP views MIM as an opportunity for fantastic growth. MPP is investing in our Noblesville, Indiana facility to make it the state of the art leader in Metal Injection Molding.”

MPP supplies MIM components for various markets, primarily for industrial applications. The company’s eight production facilities in the US and China specialise in the production of parts including custom-engineered gears and sprockets, complex structural parts, high-strength aluminium parts and components requiring unique mechanical and physical properties, for use in high stress, wear and magnetic applications.