MIM success for shape memory alloys in medical applications

August 1, 2007

Successful use of metal injection moulding (MIM) to produce complex near-net shape components from NiTi shape memory alloys is underway following research at the ‘Institute for Materials and Processes – Energy Systems (IWF-1)’ at the Forschungszentrum Jülich, Germany.

Successful use of metal injection moulding (MIM) to produce complex near-net shape components from NiTi shape memory alloys is underway following research at the ‘Institute for Materials and Processes – Energy Systems (IWF-1)’ at the Forschungszentrum Jülich, Germany.

Such alloys are characterised by their ability to display a reversible diffusionless transition between a low temperature phase (martensite) and a high temperature phase (austenite).

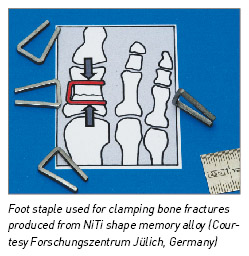

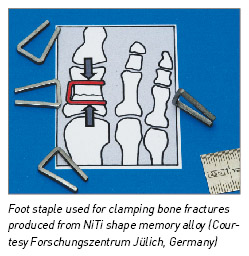

This, states IWF-1, leads to two well known effects – for example, a spectacle frame made from such a shape memory alloy can be largely deformed, e.g. by sitting on it, but it ‘remembers’ its original shape when the mechanical load decreases. NiTi is said to be an alloy showing such shape memory effects to a high degree, and IWF-1 has been investigating MIM for near net shapes such as a bushing for connecting tubes, and a biomedical staple for healing of bone fractures after foot surgery.

The MIM staple has been found to have comparable functional properties to those made from cast materials. IWF-1 is reported to be extending its research to ternary compounds NiTi-X (X=Zr,Cu) processed by MIM, and also the manufacture of porous NiTi elements by combining the MIM process with the space holder technique developed at IWV-1 for porous Ti parts.