Milacron’s DME partners with Linear to introduce conformal cooling to product range

March 21, 2017

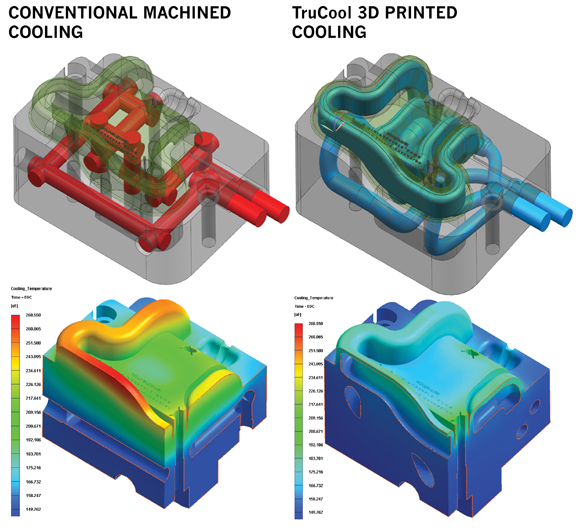

TruCool™ as compared to conventional machined cooling (Courtesy Milacron)

Milacron Holdings Corp. (NYSE: MCRN), Cincinnati, Ohio, USA, an industrial technology company serving the plastics processing industry, has announced that its DME product brand has partnered with Linear AMS to offer additively manufactured conformal cooling products to improve productivity in the moulding industry.

DME’s TruCool™ is a product line designed to offer mould makers and moulders improved mould cooling. Conformal cooling solutions are incorporated using direct metal Additive Manufacturing processes to produce complex cavities, cores and components with optimal cooling channels.

“The conformal cooling solution places cooling channels at the optimal distance from the mould surface, consistently following the geometric shape of any mould insert for any customer part, allowing the mould to maintain a targeted, consistent temperature that allows for complete thermal control with cooling times reduced up to 100%,” stated David Baucus, DME Product Manager.

Each mould is manufactured to the customers’ requirements to provide even distribution of cooling and the option to introduce individual insert temperature controls. The production process uses Direct Metal Laser Melting (DMLM) technology, allowing for lighter weight solutions with improved performance characteristics.

“Conventional mould cooling has remained largely unchanged for decades. DME’s partnership with Linear AMS is a huge step forward for the industry,” stated Peter Smith, DME President. “Our real world, in-field results show a significantly reduced total cycle time – between 15 and 60 % depending on part complexity, shortening the time needed to run the part and improving part quality. That’s a significant cost savings every moulder would be interested in.”

Linear AMS has over twelve years’ experience building metal AM conformal cooling inserts. “We’ve taken the lessons from over a decade of building DMLM parts and established design rules and process controls that enable us to make excellent quality components that meet or exceed customer expectations,” says David Hodge, Linear AMS Vice President. “We are excited to partner with DME, a leader in the moulding industry, who share our focus for serving customers with superior products. When a customer is moulding millions of parts, seeing significant process gains is a real eye-opener.”