McKinsey & Company report highlights Metal Injection Moulding in top ‘technologies of the future’

May 12, 2018

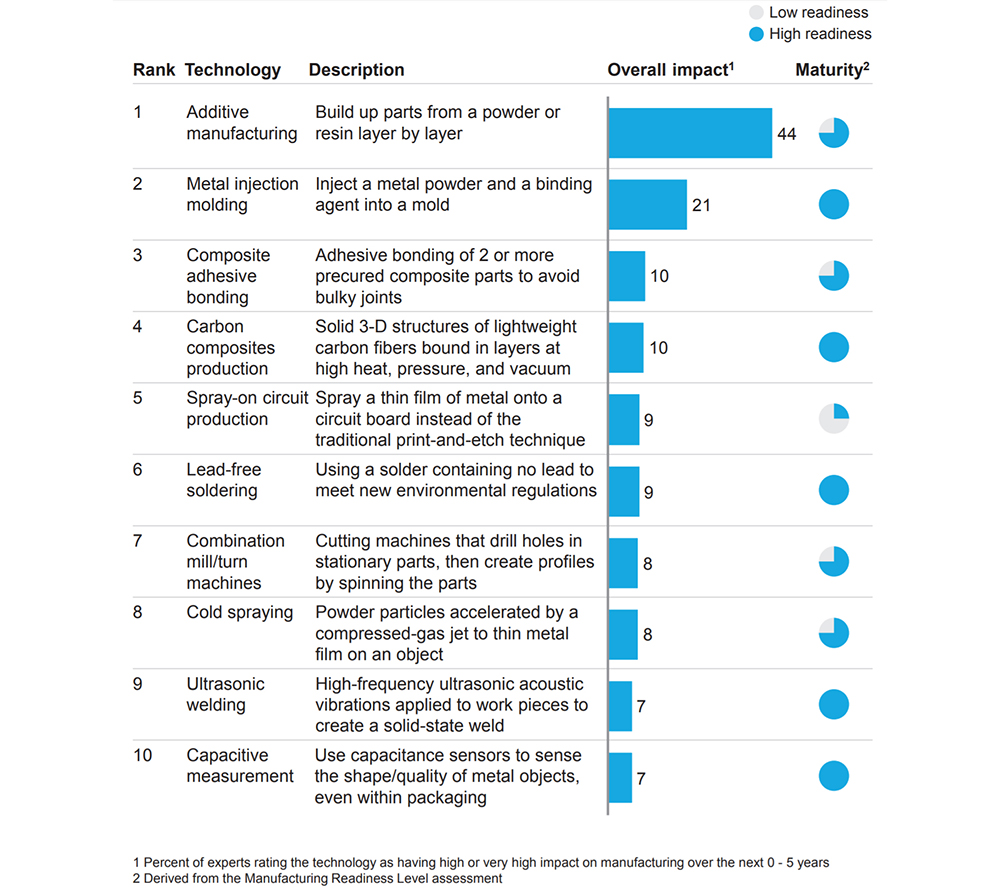

Global management consulting firm McKinsey & Company, New York City, New York, USA, has highlighted Metal Injection Moulding as second in its top ten advanced manufacturing technologies in Issue One of its report on advanced manufacturing and industry 4.0, Factory of the Future [Click to see]

Based on the McKinsey Advanced Manufacturing & Assembly survey, the report found that Metal Injection Moulding and Additive Manufacturing (AM) were consistently voted as the technologies with the most potential to improve manufacturing across a broad span of industries and geographic areas. “If you only remember two technologies from this paper, they should be Additive Manufacturing and Metal Injection Moulding,” stated McKinsey & Company.

In the survey, 21% of experts surveyed by the consultancy rated MIM as having a high or very high impact on manufacturing over the next 0–5 years, and the technology was found to be mature and to have a high readiness for industrial application. 44% of the experts surveyed stated that AM would have a high impact on manufacturing over the next 0–5 years, but the manufacturing readiness and maturity of the technology was reported to be lower.

The report found that the impact of moving from traditional milling and die casting processes to MIM could result in significant cost savings, as in the case of Bosch India, which saved 80% on the cost of a fuel control gear as a result of the reduced material waste and processing time offered by MIM. The company is now said to produce three million units a year using the technology.

While the technology is not competitive for the production of large parts, MIM was found to be an increasingly acceptable choice for manufacturers for annual part volumes over 5,000, at unit weights under 200 g and for geometrically complex components.