Mantle outlines potential for conformal cooling in tooling

July 17, 2023

Mantle, an Additive Manufacturing machine company based in San Francisco, California, USA, has highlighted the benefits of conformal cooling in a recent post to its website.

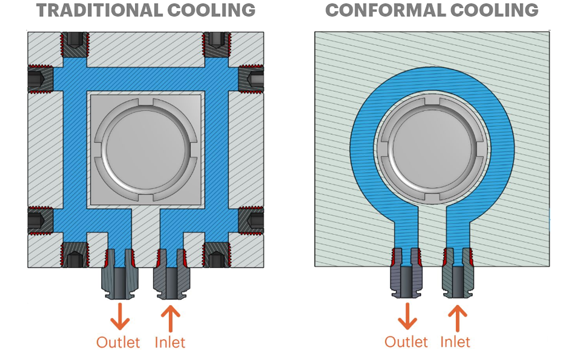

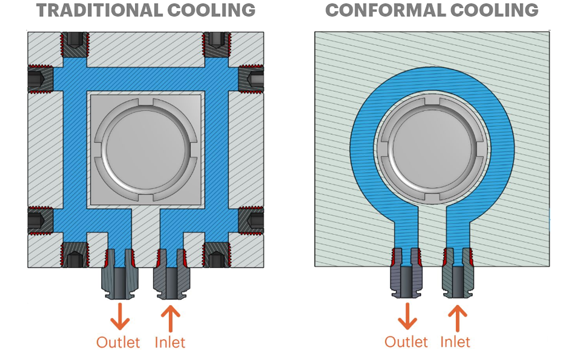

Conformal cooling refers to the integration of cooling channels that closely follow the contours and geometry of a moulded part, explains Mantle. By preserving the part’s shape, conformal cooling reportedly allows for faster and more uniform cooling, reduced cycle times, lowered per-part costs, and minimised defects. While it is said to come with manufacturing challenges, conformal cooling has reportedly offered great promise for the injection moulding industry.

The cooling channels in traditional cooling systems are designed as straight lines since the channels are built with drilling and machining processes that are limited to straight lines. Often channels will be drilled through the insert from multiple sides, with outlets being plugged to create the desired flow of water.

The report claimed that with conformal cooling, designers are not limited to straight lines, allowing them to design cooling channels that closely match the moulding part’s shape and contour. It listed the key benefits being:

- Reduced cycle times

- Better part quality

- Cost savings

- Design flexibility

- Process stability

Read the full post here.

Download PIM International magazine