Mantle delivers its first production metal Additive Manufacturing machine to Westec

August 31, 2023

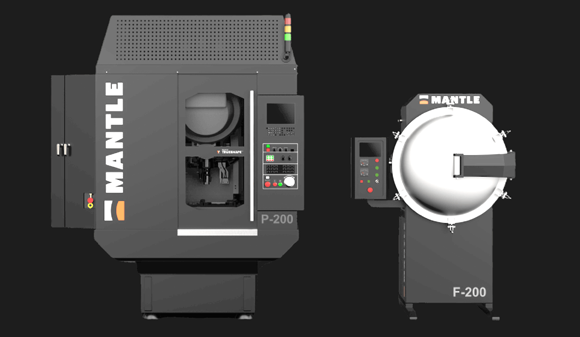

Mantle Inc., San Francisco, California, USA, has delivered its first production-specification metal AM machine to Westec Plastics, a custom plastic injection moulder and tool builder in Livermore, California. Having completed multiple beta deployments, Mantle is now shipping production versions of its P-200 manufacturer and F-200 furnace, incorporating additional hardware and process refinements.

“Having the Mantle equipment in-house enables Westec to complete prototype and production steel tooling inserts with a much shorter lead time than standard mould builds,” stated Tammy Barras, President of Westec Plastics. “This will benefit our customers by providing production-quality steel tooling with aluminium tooling lead times.”

Mantle uses its proprietary TrueShape technology – a hybrid material extrusion (MEX), CNC and sinter-based process to refine the shape of AM tools and deliver accuracy as well as good surface finish and properties. The P-200 Additive Manufacturing machine is built on a CNC platform that integrates building and machining to produce parts with the accuracy and surface finish required for tooling. The P-200 machine has a build volume of 200 mm x 200 mm x 150 mm.

A sintering stage follows using the company’s F-200 furnace. This furnace can sinter multiple parts and will support multiple AM machines. Mantle offers two tool steel materials, H13 and P2X (a steel comparable to P20), said to be durable, stable, and perform like traditional tool steels with secondary operations like machining, polishing, coating, and laser welding.

Download PIM International magazine