Lithoz to showcase multi-material parts and introduce entry-level machine at Formnext

October 18, 2021

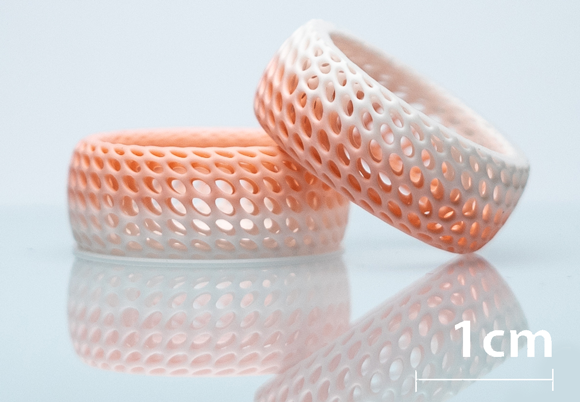

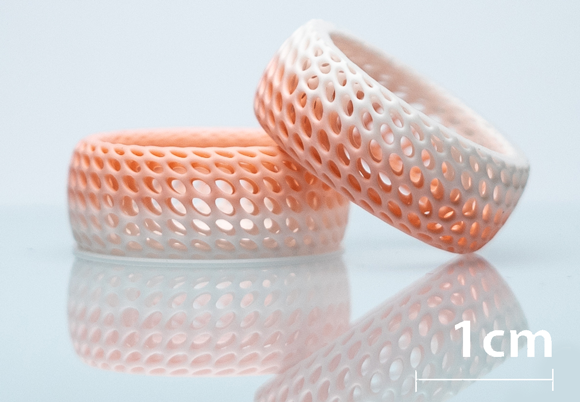

Lithoz GmbH, Vienna, Austria, will showcase a variety of multi-material parts, including ceramic/ceramic, ceramic/metal and ceramic/polymer, at Formext 2021, taking place in Frankfurt, Germany, November 16–19. The company will also provide live demonstrations of its new CeraFab Lab L30, a compact, entry-level ceramic AM machine.

The multi-material components will highlight the capability of the company’s CeraFab Multi 2M30, an Additive Manufacturing machine using a VAT photopolymerisation (VPP) process which the company calls LCM (Lithography-based Ceramic Manufacturing). Using the CeraFab Multi 2M30 it is possible to additively manufacturing two materials simultaneously, enabling the production of accurate parts in various material combinations for industries such as aerospace, biomedical, energy and electronics.

Lithoz’s latest machine, the CeraFab Lab L30, was launched in April this year and has been specifically developed for the customisation and small-scale production of oxide ceramics. The machine offers open system technology and is said to be well suited to academics, researchers, and material & application developers.

“Despite being an entry-level machine, companies can achieve the quality they would expect from a Lithoz machine,” stated Dr Johannes Benedikt, CTO and co-founder of Lithoz. “The open system technology offered by the CeraFab Lab L30 gives businesses the opportunity to use a well-known, high-quality technology to realise their ideas and develop their own materials.”