Lithoz highlights Ceramic Additive Manufacturing at leading dental event

March 15, 2023

Lithoz, Vienna, Austria, showcased its new lithium disilicate material for dental Additive Manufacturing at IDS, a global trade fair for the dental community held in Cologne, Germany, March 14-18, 2023.

The additively manufacturable lithium disilicate powder, jointly developed with Ivoclar, is expected to open up a long-awaited path to the patient-individual serial production of high-profile, all-ceramic dental restorations. The process allows veneers as thin as 0.3 mm and crowns with high levels of detail, especially at the occlusal surfaces. In a single build, a multitude of patient-specific, aesthetic restorations can be created.

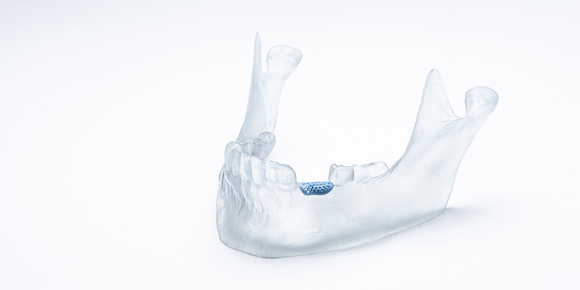

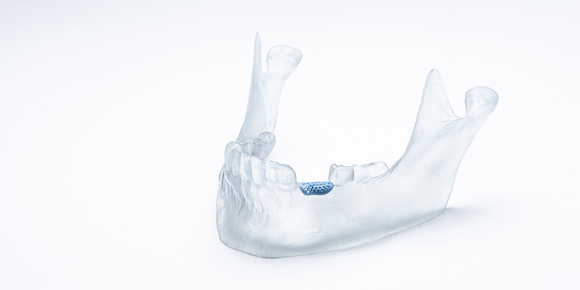

At the Lithoz booth, visitors were able to examine such restorations and be informed about the status of the project in detail. Further dental applications were also on display, including a bioresorbable jawbone (hydroxy apatite or tricalcium phosphate) and additively manufactured dental implants made of zirconia (TZP-A) or alumina-toughened zirconia (ATZ).

Lithoz utilises Lithography-based Ceramic Manufacturing (LCM) technology, a Vat Photopolymerisation (VPP) process, which enables the construction of highly complex and ultra-fine ceramic structures which were considered unattainable with conventional processes. The CeraFab System S65 medical Additive Manufacturing machine, which was specially developed for the dental and medical sector, combines the extensive design freedom of Additive Manufacturing with the outstanding properties of ceramic materials to meet the high demands of the dental sector.

Following approval, it was stated that the USA will be the first market where the lithium disilicate products will be available to customers.

Download PIM International magazine