Lithoz delivers CeraFab Lab L30 to Penn State to boost ceramic research

June 30, 2023

Lithoz GmbH, headquartered in Vienna, Austria, has delivered a CeraFab Lab L30 to Penn State University, USA, providing researchers at Penn State’s Material Research Institute access to the necessary tools for producing high-resolution ceramic parts.

“This will be part of a user facility here at Penn State, in the Nanofabrication Lab,” stated Amira Meddeb, Associate Research Professor at the Materials Research Institute. “The number one reason we acquired it is to allow more capabilities not just for the Penn State community, but for our extended user community that we work with including other higher education institutions and industry.”

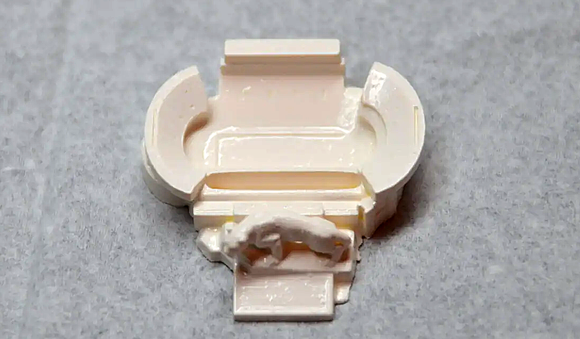

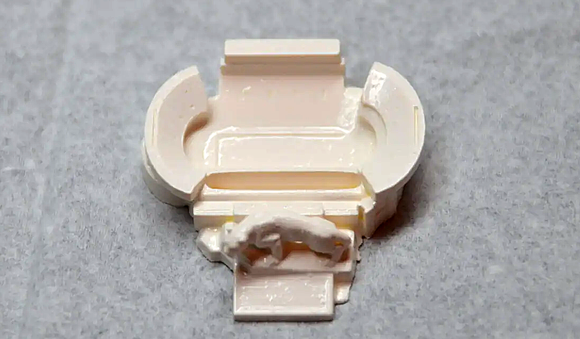

The CeraFab Lab L30 is an entry-level machine with the ability to additively manufacture a variety of ceramic materials, including those in Lithoz’s materials library and custom materials. It retains all the power of Lithoz’s Lithography-based Ceramic Manufacturing (LCM) technology, enabling the production of very high-resolution parts and full density of ceramics that would be comparable in properties and microstructure to ceramics that are made by traditional manufacturing methods.

“While ceramics are typically extremely hard to traditionally manufacture and are so delicate, this LCM technology really enables the production of multiple iterations of a part with different geometries and dimensions until you achieve the part you need,” stated Shawn Allan, Vice President of Lithoz America. “Using this machine, it will be possible for Penn State to produce custom scientific tools for other researchers such as custom-designed crucibles and microreactors, which until now have been costly or difficult to source. This will, therefore, further the work and efforts of the entire research team.”

Chad Eichfeld, Associate Research Professor and Director of Operations in the Nanofabrication Lab, shared, “We can work with researchers to do the design of the material, the 3D printing of the material, but you can also do the characterisation here. Having all of that together lets you actually do the rapid iterations of ceramic production that are necessary for our researchers’ success.”

“At other universities some of the processing that is done in Amira’s lab and my lab you might give to a technician, and they would do the work for you. But we are all hands-on. That is powerful, with our graduate students and even some undergraduates getting hands-on experience with state-of-the-art technology here. That experience will be really rewarding for them as they begin their career,” Eichfeld concluded.

Download PIM International magazine