Lithoz and Himed partner on medical-grade bioceramics

August 14, 2023

Lithoz GmbH, Vienna, Austria, and Himed, based in New York, USA, have signed a strategic research partnership agreement to further accelerate the development of medical-grade bioceramics. Together, the partners will focus on implants using biocompatible calcium phosphates, targeting the strongly increasing demand for innovative bioceramic feedstocks for Additive Manufacturing.

The joint effort, which reportedly follows on from feedback Lithoz received during launch of its LithaBone HA 480 material at last year’s Formnext, includes Himed’s acquisition of a CeraFab S65 medical Additive Manufacturing machine.

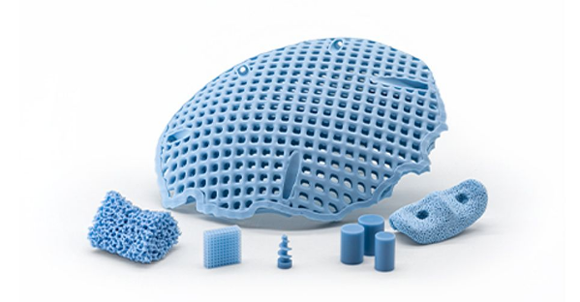

The tricalcium phosphate or hydroxy apatite-based LithaBone medical ceramics have reportedly proven to be an attractive alternative to metals used in human surgery. It has also been reported that Lithoz has received numerous innovation study requests involving these bioceramics, as the precision and design flexibility of Lithoz LCM technology is said to possess huge potential for innovation when it comes to lattice structures and porosities achieving the desired ideal level of osteoconductivity.

First-phase research will occur at Lithoz’s US facility in Troy, New York, this summer, conducted by a joint team of materials scientists. Himed will install a new Lithoz CeraFab S65 Additive Manufacturing machine at its facility in Long Island in the early autumn, with the aim of allowing the company to more rapidly experiment on site and run important analytical testing at its in-house laboratory. The addition of a CeraFab S65 at Himed also broadens their R&D service offerings, adding rapid prototyping of different forms for clients who contract with Himed to conduct unique biomaterials research.

Dana Barnard, Himed CEO, shared, “Himed understands CaP optimisation and how to scale it for a growing market. We’ve refined many calcium phosphates to strengthen their healing potential, but most of these were targeted toward surface coatings on traditionally manufactured titanium implants. Lithoz’s remarkable 3D printing technology allows a whole new direction for our products, in which we can use CaP to its greatest advantage — as a biomimetic material within the implant structure itself that can be replaced by a person’s own natural bone over time.”

This strategic partnership represents a first step in growing the range of biocompatible materials suitable for highly customised, patient-specific medical solutions that can be additively manufactured on demand. Over the last thirty years, calcium phosphates such as hydroxy apatite have reportedly gained widespread use in implantable devices, bone putties, and grafting materials for their similarity to natural bone, and can aid the organic regrowth of hard tissue at the implantation site. Since 1991, Himed has collaborated with different medical implant manufacturers to develop and optimise various CaP powders and surface treatments for osseointegration. The partnership with Lithoz, however, looks to allow new opportunities for Himed in the medical Additive Manufacturing market beyond bioactive surface treatments and postprocessing of implants.

“This is definitely a big milestone for our partnership, and just a first starting point for a mutual beneficial collaboration for Additive Manufacturing of bone replacement,” commented Lithoz CEO, Dr Johannes Homa.

Download PIM International magazine