LightForce Orthodontics closes Series C funding with $50 million investment

November 11, 2021

LightForce Orthodontics, Cambridge, Massachusetts, USA, has closed its Series C funding round with a $50 million investment from new investor Kleiner Perkins and existing investors Matrix Partners, Tyche Partners and AM Ventures, reports TechCrunch.

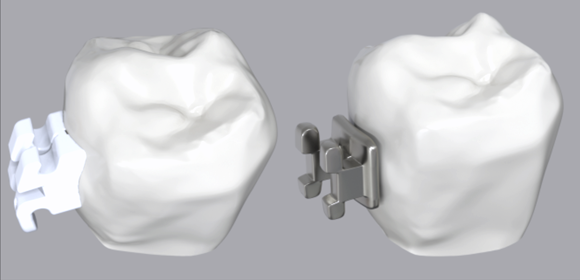

LightForce technology provides additively manufactured bracket systems for orthodontics using ceramic material which is said to be virtually identical to familiar injection moulded brackets, but is specially formulated for Additive Manufacturing. The company has seen large-scale growth since the closing of its Series B funding in October 2020, including a 500% increase in revenue and 300% team growth.

“We raised a little bit earlier than we had planned. There were some very well-known VCs that were keeping tabs on us that had seen us in the past, but we were a bit too early for them. Kleiner Perkins was always one that was on my mind, as one that I would love to work with – especially with Wen Hsieh himself. He has a deep background in 3D printing and hard tech. He’s done a lot of the best hard-tech deals,” stated Dr Alfred Griffin III, DMD, PhD, MMSc, CEO and co-founder of Lightforce. “Kleiner Perkins is one of the only venture capital groups that has done anything significant in orthodontics – it was twenty years ago, but Align Technology changed orthodontics, for the better in my opinion. Two value props came out of Align Technology: one was the aesthetic benefits, which unlocked the adult segment. The second thing is the digital nature of what they do.”

Wen Hsieh, the Kleiner Perkins partner who led the investment, added “A lot of these innovations come from people who are not from the industry…. Because [Dr Griffin’s] a doctor himself, he already knows where to insert into their workflow. What part of their normal workflow is eliminated, what part is enhanced, how they can spend more or less time, how it impacts the dental tech, how it impacts the footprint of the office, how it impacts how often the patient has to come in, and so on. Meanwhile, Alfred is taking in the knowledge from other areas, such as from simulation and from 3D printing.”

This latest $50 million investment will be utilised by LightForce to scale operations and market efforts, something which may prove a challenge due to the necessarily bespoke nature of these hybrid ceramic braces.

“Scaling – mass customisation – is a very unique problem that most talk about in theory, but very few have dealt with in practicality,” Griffin commented. “There’s around 200 of us in the company right now, and we will probably double that over the next year. Sales and engineering are probably going to be the biggest expenses, but in terms of headcount, we will need to grow the most in manufacturing technicians, both in terms of physical and digital manufacturing.”

Griffin concluded, “The market we are really unlocking is the teen and adolescent market, which represents 75% of all cases in the U.S. Think about adolescent psychology: that’s when kids are forming their sense of self. I can’t tell you how many cases I’ve seen personally as an orthodontist, where mom will come in and say ‘my son gets teased’ for this or for that. With LightForce, we can help that patient faster and reduce the number of appointments and reduce the amount of time they have to be out of school. We get them to a better result by leveraging technology.”