Japan’s MIM industry output drops in 2019

October 1, 2020

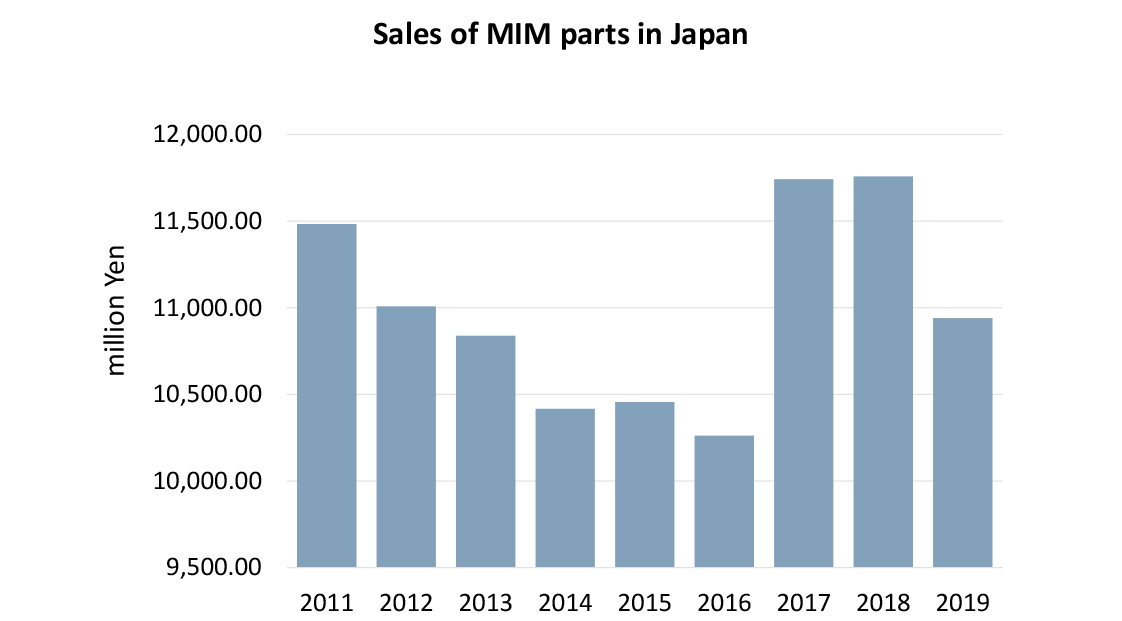

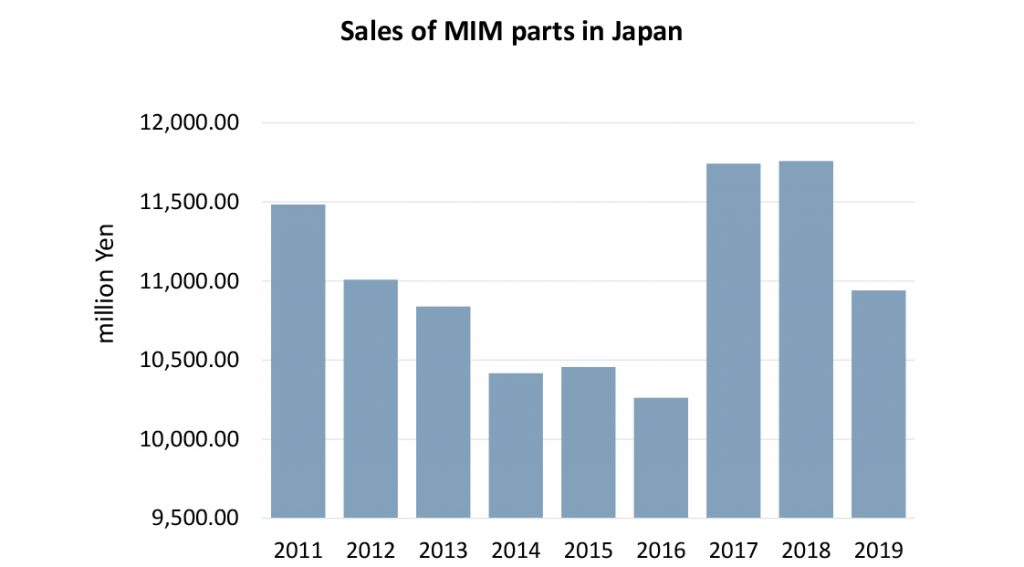

After a strong performance in 2017 and 2018, the Japanese MIM industry reported a significant drop in output for 2019, with sales of JPY 10.94 billion recorded ($103.7 million at current exchange rates) – a reduction of 7% compared with the previous year (Fig. 1). According to the Japan Powder Metallurgy Association (JPMA), which collected statistical data from nineteen companies involved in MIM production in the country, the drop in sales can be attributed to tax increases, natural disasters and trade friction between major economies. It was stated that a bigger decrease is forecast for 2020 because of the coronavirus (COVID-19) pandemic.

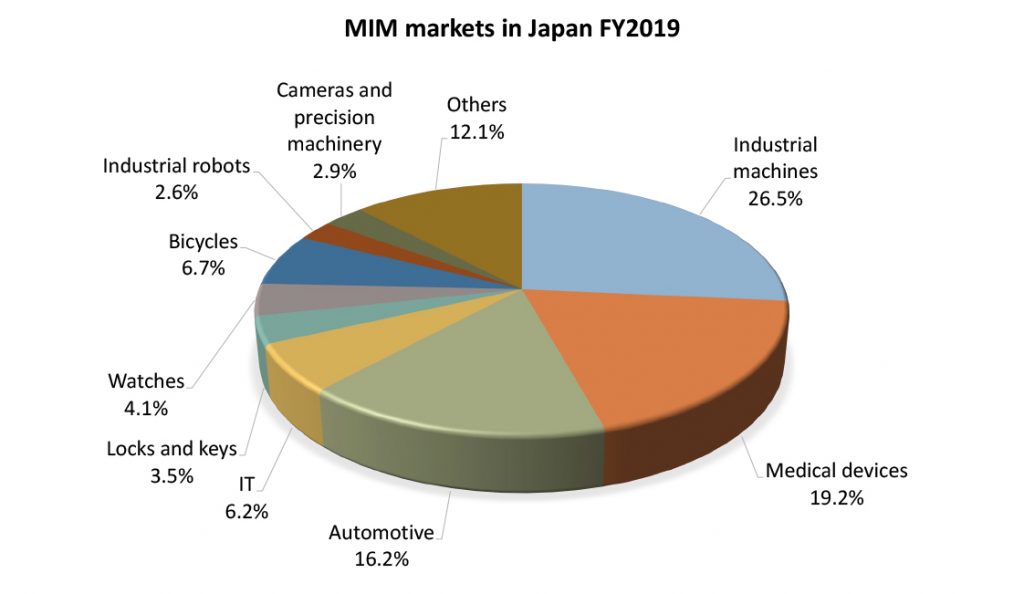

Fig. 2 shows that the main markets for MIM in Japan were relatively stable in comparison with recent years. Industrial machine parts accounted for 26.5% of production (previous year: 29%), medical device parts accounted for 19.2% of production (previous year: 20.2%) and automotive parts accounted for 16.2% of production (previous year: 16.1%). The total percentage of these core MIM markets is 61.9%. In other sectors, bicycle parts saw a year on year increase of 23.2%. MIM production for industrial robots also saw a growth increase as manufacturers moved to increase automation in industrial manufacturing.

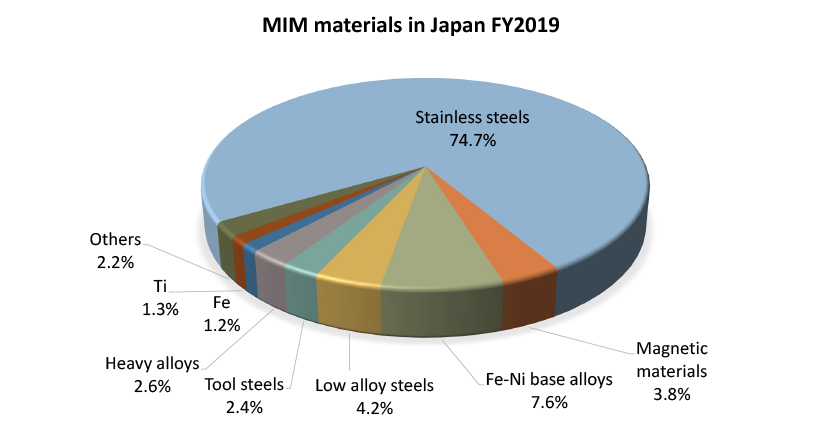

Fig. 3 shows the breakdown of MIM materials in Japan in 2019. Stainless steels accounted for 74.8% of production (previous year: 73.8%). Together, stainless steels, Fe-Ni materials, low-alloy steels and magnetic materials accounted for over 90% of production. Magnetic material saw a decrease in use for the second year in a row, whilst titanium continued to fluctuate, with most demand coming from the medical device sector. Looking ahead, growth in the production of heat resistant MIM materials is anticipated.