Husky launches Ultra SideGate™ Inline hot runner for injection moulding applications

October 24, 2017

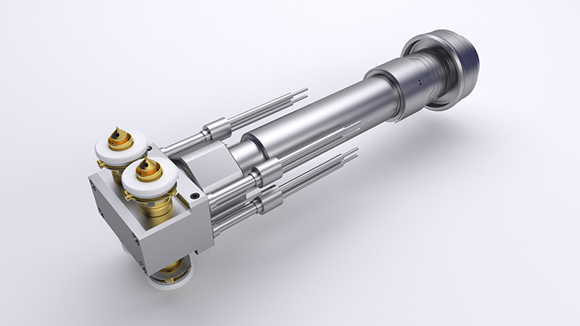

Husky’s new hot runner for injection moulding (Courtesy Husky)

Industrial injection moulding technology supplier Husky Injection Molding Systems, Bolton, Canada, has released a new type of inline hot runner for injection moulding applications. According to the company, the Ultra SideGate™ Inline hot runner has been designed and optimised for challenging applications with high-balance requirements such as long, thin parts and is ideal for part spacings as low as 18 mm. The hot runner also offers optional tip control technology, enabling moulders to ensure the best part quality possible for challenging applications.

The inline option provides the same features of Husky’s standard Ultra SideGate, which allows for high cavitation moulds with a small footprint, offering mould makers additional design flexibility. In addition, by direct-gating parts with Ultra SideGate, Husky states that moulders could achieve significant materials savings, faster cycle times and better performance across a wider temperature range during injection moulding. The technology also allows direct access to individual tips without removing the mould from the injection moulding machine, reducing maintenance time.

The new hot runner is reported to leave virtually no vestige on finished parts (~0.05 mm vestige). By allowing for the use of a single-piece cavity in the design of the mould, the quality issues that often accompany split cavity designs are avoided, such as flash on finished parts, which can occur if the cavities are misaligned. This is particularly critical in the medical industry.

The Ultra SideGate Inline features nozzle tips which are mounted separately from the nozzle housing into one-piece cavity inserts before hot half assembly. According to Husky, this approach minimises the impact of thermal expansion on tip position, which can impact balance and gate quality.

Stefano Mirti, Husky’s President of Hot Runners and Controllers, stated, “Hot runners are the most critical component in the injection moulding process. This is why we are so focused on improving hot runner design and performance while also finding ways to help customers reduce their cost. Ultra SideGate Inline is another example of an innovation that accomplishes this goal. This new technology provides the same superior part quality, speed and efficiency that our customers have grown accustomed to with the added benefit of tighter part spacing.”