HRL Laboratories develops method for AM of fracture-resistant ceramic matrix composites

October 26, 2020

HRL Laboratories, LLC, Malibu, California, USA, a corporate research and development laboratory owned by the Boeing Company and General Motors, has developed a novel method to additively manufacture components from fracture-resistant ceramic matrix composites (CMCs). The method is set to be published in the December 2020 issue of The Journal of the American Ceramic Society.

Ceramic parts resist corrosion and wear, and have excellent high-temperature capabilities that make them desirable for application in propulsion and energy generation systems as well as chemical processing equipment and medical implants. However, their use has been limited by the difficulty of shaping ceramic materials, a problem that can be solved using Additive Manufacturing. With properties commensurate with traditionally processed technical ceramics, HRL’s technique is said to allow free-form fabrication of high-performance CMC components.

“All ceramic parts, whether traditionally processed or 3D printed, have small defects, such as tiny voids, that arise during processing, handling, and service,” stated Mark O’Masta, HRL researcher and first author on the paper. “The problem is, when stress is applied to that region, the defect can become an uncontrolled crack that results in catastrophic failure of the entire part. It basically crumbles. Adding a ceramic reinforcement to a ceramic matrix is a common method to create defect-tolerant parts.”

“The challenge we addressed in this project was integrating this toughening solution with our 3D printing process,” continued O’Masta. “We can now add these reinforcements in large volume fractions to significantly toughen our 3D printed ceramic parts. We’ve essentially made a brittle monolithic material into a durable composite. As an extra benefit, adding reinforcements relaxed some of the processing constraints.”

A ceramic fabrication technique must result in as low a void fraction as possible so as not to compromise the final component. If too high, a fraction of the reinforcement element is added, the elements will impinge upon surpassing their packing limit and the part is subsequently weakened by the process. Through careful measurements and characterisation, HRL states that it achieved the ‘sweet spot’, determining the processing bounds for the most durable CMCs.

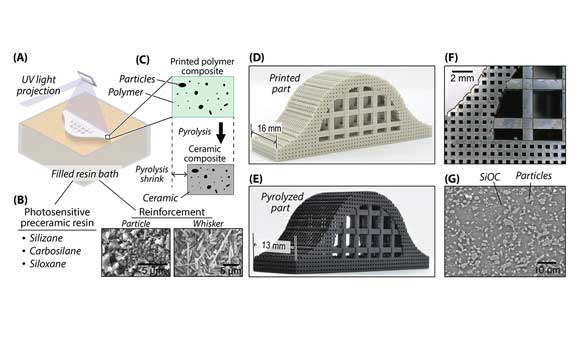

Continuing from the additively manufactured ceramic technique published in Science in 2016, the HRL team utilised UV curable preceramic polymers. A Vat Photopolymerisation (VPP) Additive Manufacturing machine cures the polymer, building parts in a rapid layer-by-layer method. In the current experiments, a siloxane-based preceramic resin was reinforced with inert particles. The additively manufactured polymer parts were then converted to silicon oxycarbide (SiOC), a glassy ceramic, through an extreme heating process called pyrolysis.

Ekaterina ‘Katya’ Stonkevitch, HRL engineer and second author, commented, “Finding the ideal process to include these reinforcement elements was quite challenging and eluded us for some time. Through a detailed study and careful inspection for defects using light and electron microscopy, we were able to identify the right processing conditions. With that information we printed additional parts to do mechanical testing on, and that’s when we figured out our fracture toughness and mechanical strength. We also discovered that with the reinforced material we could print parts thicker than before.”

The ‘Additive manufacturing of polymer‐derived ceramic matrix composites’ article is available here.