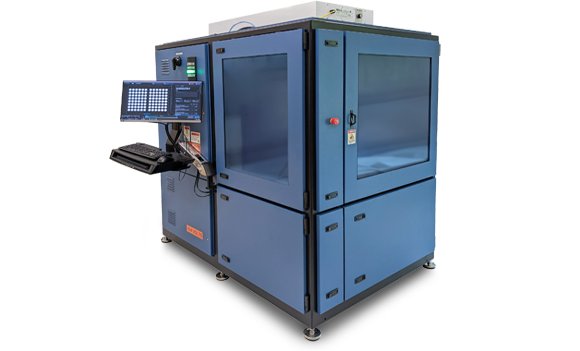

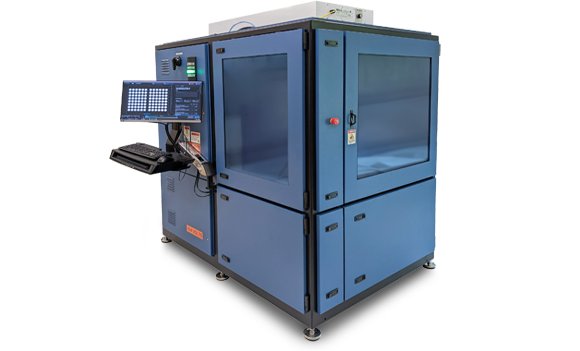

Holo launches H200 machine for high-volume metal part production

November 16, 2023

Holo Inc, based in Newark, California, USA, has launched the H200 production metal Additive Manufacturing machine. The H200 uses Holo’s PureForm™ AM platform to produce highly-precise metal parts based on a sinter-based Vat Photopolymerisation (VPP) process.

Over the past nine months, Holo reports it has been using the H200 in its Additive Manufacturing services to supply complex metal parts with high resolution and precision. The components demonstrate fine detail up to 50 µm and maintain strict tolerances within +/-25 µm. Unique to PureForm™, the final parts match the surface smoothness of commercial MIM parts, exhibiting a roughness of 1-3 µm Ra. This is said to eliminate the need for additional machining or polishing required by other metal AM technologies.

Holo’s PureForm™ commercial material offering currently includes stainless steel grades 17-4PH and 316L, along with pure copper. The portfolio is extending to include Inconel and Ti-64 on a pre-commercial basis. All commercial materials from Holo meet the MPIF-35 specifications.

“True to CAD™ from Holo’s technology means that our H200 system produces MIM-quality parts without the mould,” stated Holo co-founder and Chief Strategy Officer Arian Aghababaie, PhD. “For most applications, our technology does not require parts to go through any post-machining or polishing; it sinters parts to spec for a first-time-right approach suited for demanding, high-volume end-use applications.”

Having been developed over multiple generations of machines and with over 10,000 parts shipped to customers so far, Holo’s H200 has demonstrated its readiness for commercial use. Customers from demanding sectors such as medical, aerospace and defence, consumer electronics, and the semiconductor industry are reported to be adopting the technology.

“We are thrilled for customers to gain access to the H200,” stated Holo CEO Hal Zarem, PhD. “Production volumes of parts in fields like surgical instruments will be within reach, finally fulfilling the promise of Additive Manufacturing as a scalable, production-ready suite.”

Download PIM International magazine