Freeman Technology’s powder flow solutions displayed at Ceramics Expo 2019

May 7, 2019

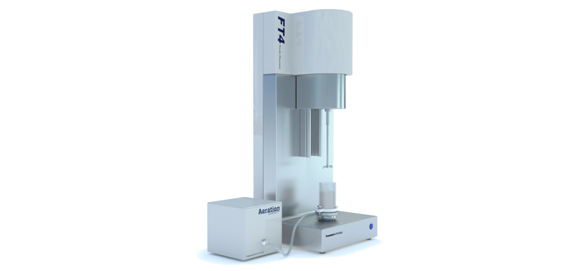

Freeman Technology displayed its powder flow solutions at Ceramics Expo, including the FT4 Powder Rheometer® (Courtesy Freeman Technology)

Powder flow technology company Freeman Technology, Tewkesbury, Gloucestershire, UK, recently acquired by the Micromeritics Instrument Corporation, Georgia, USA, exhibited its powder flow solutions at Ceramics Expo 2019, April 30–May 1, 2019, in Cleveland, Ohio, USA. Freeman provides material characterisation solutions aimed at optimising process performance, increasing productivity and improving quality in a diverse range of sectors, including ceramics.

Solutions displayed by Freeman at Ceramics Expo included the FT4 Powder Rheometer®, a powder flow tester that combines dynamic methodologies, automated shear cells (in accordance with ASTM D7891) and a series of bulk property tests to quantify powder behaviour in terms of flow and processability.

Dynamic measurements of a powder in motion reportedly not only quantify flowability, but also enable the investigation of the impact of air on the powder. Samples can be analysed in consolidated, conditioned, aerated or even fluidised states. The FT4, along with the Uniaxial Powder Tester (UPT), is said to provide an accurate and repeatable measure of the uniaxial Unconfined Yield Strength (uUYS) of a powder to assess and rank flowability.

According to the company, a reliable powder characterisation technique that is relevant to the process makes it easier to develop materials that are suitable for application in the ceramics industry. Representatives from Freeman Technology were on hand throughout the event to discuss aspects of material characterisation, including how powder testers deliver process-relevant measurements to predict in-process behaviour and optimise productivity and quality.