ExOne releases X1D1 automated guided vehicle concept

September 22, 2020

The ExOne Company, North Huntingdon, Pennsylvania, USA, has released a concept rendering of its new X1D1 automated guided vehicle (AGV), designed to enable efficient transport of build boxes through the Binder Jetting process.

The X1D1 will initially be offered as an option for customers of ExOne’s new X1 160Pro™ production metal Additive Manufacturing machine, which will begin shipping later this year. The 160Pro will be offered with either a standard conveyance system or the new X1D1, providing manufacturers with greater layout flexibility and efficiency options.

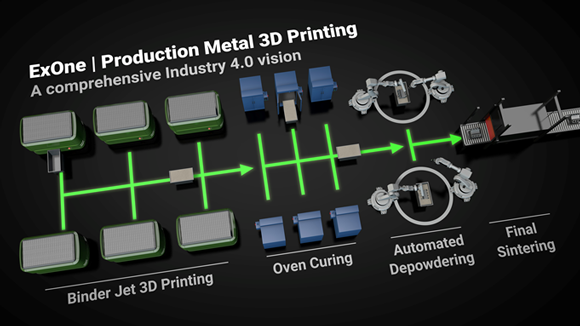

The X1D1 AGV will lock into place at the front of the 160Pro, and will be able to roll a build box into and out of the machine. With a build volume of 160 litres, a full build box of metal powder will often weigh more than 700 kg(1,500 lb). After the build process, the X1D1 will transport the build box to a curing oven, where the parts are dried, before moving to an automated depowdering and cleaning station before final sintering.

“As part of our discussion with manufacturers, we’ve updated our vision for the production Binder Jetting work cell, developing an option that provides high-volume manufacturers with more intelligent flexibility and better use of factory space,” stated John Hartner, ExOne CEO.

According to ExOne, the AGV is said to be able to support multiple AM machines and processes efficiently, thus reducing the total footprint of the machine and simplifying timed movements between processes.

“While ExOne’s production metal 3D printers will remain the centrepiece of our digital manufacturing vision, we’re looking to streamline the entire sequence of processes around our systems with automation, software and remote monitoring and controls,” Hartner continued.