Epson develops industrial MEX Additive Manufacturing machine

March 9, 2022

Japan’s Seiko Epson Corporation has developed a pellet-based industrial Material Extrusion (MEX) Additive Manufacturing machine which is compatible with a variety of third-party materials. The new machine is expected to be used in a wide range of applications, including in the production of parts for final products, and will enable users to mass-customise their goods in support of small-batch production.

Through its subsidiary, Epson Atmix Corporation, Seiko Epson is a leading producer of water atomised metal powders for Metal Injection Moulding (MIM), as well as being a leading Japanese producer of MIM parts for in-house use as well as for external customers.

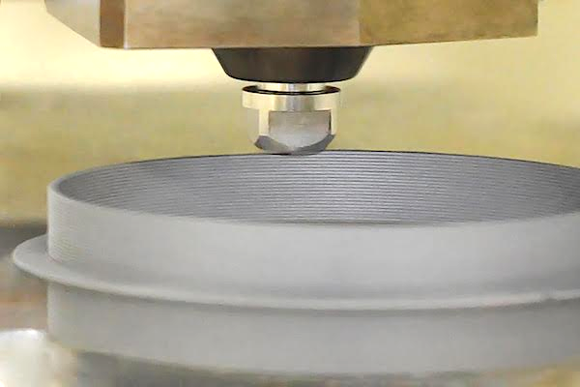

The machine employs a MEX technique that is achieved using a flat screw (an inline screw with a flattened configuration), similar to those found in Epson’s currently available precision injection moulding machines. This extrusion method enables the Additive Manufacturing machine to be used with a variety of common third-party polymer materials, as well as pelletised metal/binder feedstocks.

The amount of the chosen material injected is precisely controlled by regulating the pressure within the head and by regulating the action of a valve in concert with the build speed. Epson employs a unique mechanism to precisely control this temperature and achieve both strength and accuracy.

The new Additive Manufacturing machine is said to be ideally suited to mass customisation, as it can produce small batches of parts tailored to customers’ needs, with higher quality, shorter lead times, and at cheaper costs than traditional manufacturing processes.

Epson debuted the machine at the International Robot Exhibition 2022, which opened on March 9 at Tokyo Big Sight, Japan.