Epson Atmix launches high sintered density 316L stainless steel powders for MIM

December 7, 2016

Fig. 1 High-quality mirrored surface on a MIM 316L casing using Epson Atmix’s new ultrafine powder grade

Epson Atmix Corp., Hachinoke-shi, Aomori-ken, Japan, is a leading producer of ultra-fine (-20 µm to sub-micron particle size) metal powders using its high pressure water atomisation technology. The company introduced a new 316L stainless steel grade power at the World PM2016 Congress and Exhibition in Hamburg, October 9-13, which the company states achieves near full density (99.5% or higher) in sintered Metal Injection Moulded components.

The company believes that the newly developed powder achieves density levels which would be impossible using conventional MIM technology and allows the production of mirror surface finish on MIM parts after polishing such as the watch case shown in Fig. 1.

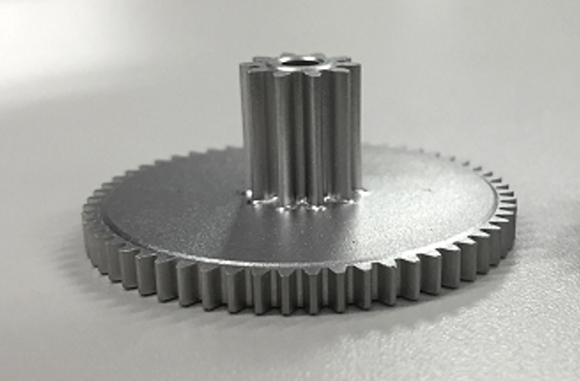

The company also introduced a 316L stainless steel granulated powder in Hamburg which allows the conventional powder die compaction and sintering of ultrafine powders to very high densities and with excellent mechanical properties and dimensional tolerances. A double gear made from the new granulated 316L powder having diameters of 8 mm and 31 mm respectively is shown in Fig. 2.

Fig. 2 Double gear made from granulated ultrafine powders developed by Epson Atmix Corp

Epson Atmix is currently also constructing a new factory for superfine alloy powders, excluding amorphous alloy powders, which are used in the production of high-performance precision Metal Injection Moulded components for numerous sectors including automotive, 3C, wearable products and medical devices.