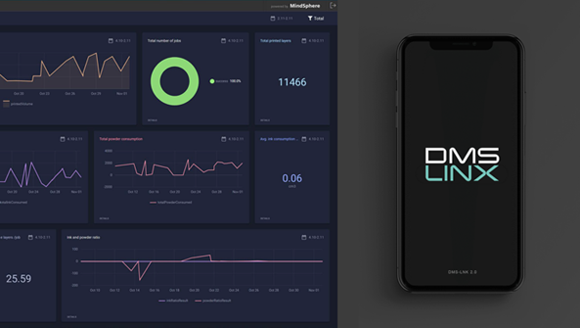

Digital Metal launches digital platform interface

November 18, 2021

Digital Metal, part of Sweden’s Höganäs Group, has launched the DMS-LNX 1.0 Control Panel Interface. The system, co-developed with automation partner Siemens, is said to provide a complete overview of ongoing build processes, with the ability to review specific details and receive alerts and prompts.

“Producing millions of parts in-house has taught us a lot about this process,” stated Christian Lönne, CEO of Digital Metal. “It became clear to us early on that successfully industrialising metal Binder Jetting [BJT] is not just about the printer, but also about automating all the process steps.”

As a total system supplier, Digital Metal hopes to realise the full potential of metal BJT as an established technology for industrialisation and serial production. With the recent launches of two new process line machines – DPS 1000 for automatic de-powdering, and PPS 1000 for closed-powder handling – the company is said to have progressed towards its goal of hands-free production.

Digital Metal Binder Jetting is based on the company’s own serial production experience, and closed loop manufacturing is expected to deliver a robust, reliable, completely digital solution for a variety of industries and markets

“This will enable us to deliver a truly digital manufacturing experience,” continues CTO Hans Kimblad. “The launch of DMS-LNX 1.0 provides an excellent base for implementing a digital thread through the entire manufacturing process.”

The new technologies from Digital Metal will be showcased at Formnext, where visitors can remotely view machines at work in Sweden from the Digital Metal (Hall 12, D101) and Siemens (12.1, D81) stands.