Desktop Metal qualifies D2 tool steel for Studio System 2

December 7, 2021

Following the recent qualification of D2 tool steel for its Production System™, Desktop Metal, Inc., Boston, Massachusetts, USA, has announced the qualification of the high-carbon, high-chromium air-hardening material for its Studio System™ 2. The company is reputedly the first to offer the material in a two-step bound metal Additive Manufacturing process.

“D2 tool steel has traditionally been a challenging and expensive material to work with,” stated Jonah Myerberg, co-founder and CTO. “With this material now available on the Studio System 2, we’ve streamlined production of D2 parts to just two simple steps for improved affordability and accessibility. We are excited to be able to offer our customers this new material with higher hardness after heat treatment than all of the other Studio System materials qualified to date, unlocking new applications that require tooling material grade strength.”

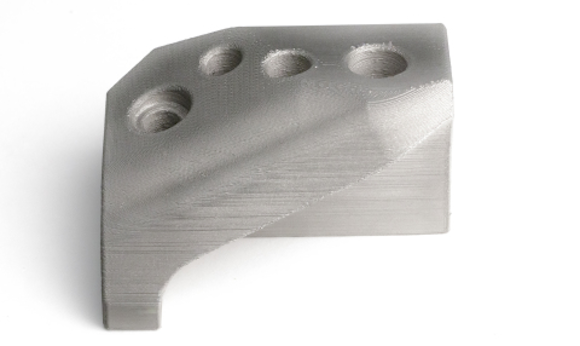

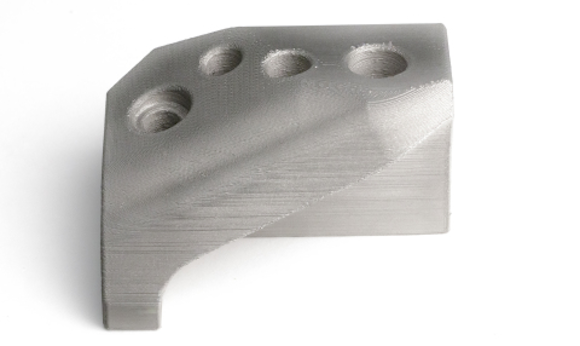

One example of a key-use case is an aerial cam cutting section tool, a component of the stamping dies used to make frame components on high-volume vehicle manufacturing lines. D2 tool steel is a key material for this application because of its high hardness and wear resistance, critical for stamping applications where the tool is subjected to repeated impact while forming. These tools are traditionally produced in low volumes using advanced machining techniques and slow feed rates because of the material’s hardness. With the Studio System 2, businesses can additively manufacture these tools in D2 tool steel at low volumes more cost-effectively while reducing complex machining operations as well as CNC fixturing and tool wear.

“Egar Tool and Die is a rapidly growing manufacturing company for automotive stamping dies, production stampings and welded assemblies and we have been eagerly awaiting the launch of D2 for our two Studio Systems,” said Colin Kools, Director of Additive Manufacturing, Egar Tool and Die. “The release of this material will serve to push our tooling design to new heights and will give us the critical material properties and hardness needed for our die components.”