Desktop Metal qualifies commercially pure copper for Production System

December 22, 2021

Desktop Metal, Boston, Massachusetts, USA, has qualified C10300, commercially pure copper with over 99.95% purity, for use on the Production System™ platform, which utilises the company’s Single Pass Jetting™ (SPJ), a form of Binder Jetting (BJT) technology. Due to copper’s excellent thermal and electric conductivity, this addition is expected to widen the scope of SPJ technology into the production of high-performance parts at scale across a broad variety of industries, including automotive, aerospace and electronics.

“Copper has been a highly requested material from many of our customers and prospects, and has applications spanning a broad variety of industries, from thermal hardware found in air and liquid cooling systems to conformally cooled coils for transmission of high frequency currents,” stated Jonah Myerberg, co-founder and CTO. “We are excited to be able to expand our extensive Production System materials portfolio to support customers looking to 3D print electrically and thermally conductive components at scale and at a fraction of the cost of conventional manufacturing methods.”

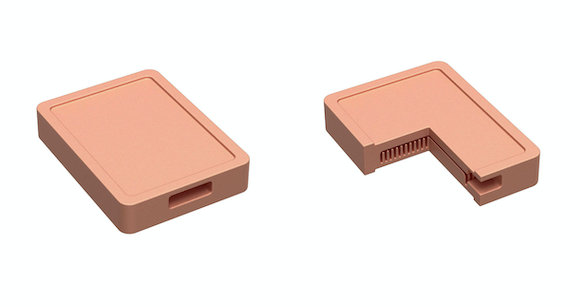

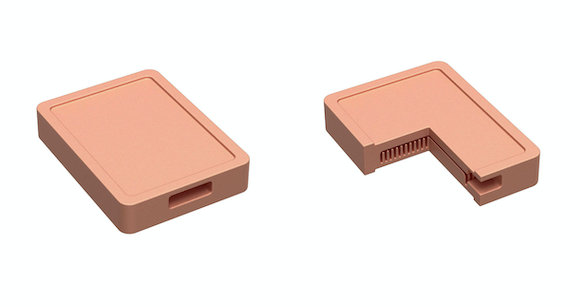

One application highlighted by the company is the additive manufacture of liquid cooling plates, used to regulate temperatures on high-performance microprocessors. While traditional production methods require the parts to be made from multiple components, the BJT technology employed by the Production System builds the plates as single pieces. This enables hundreds of cooling plates to be additively manufactured per day, now from a material that is said to maximise the heat dissipation from the electronic chip to the cooling fluid.

As well as for cooling plates, commercially pure copper is reputed to be an ideal material for any application which requires heat or electricity transfer, such as pucks and manifolds, heat sinks, heat exchangers, and bus bars used in power-intensive electrical applications.