Characterisation of ceramic injected moulded biocompatible oxide ceramic parts

September 4, 2023

There has been a significant increase over the past fifty years in the number of elderly people in the global population, which in turn has led to the need to raise awareness of osteoporosis caused by ageing and the growing demand for artificial bone materials as bones become more fragile and fracture and require to be repaired or replaced.

Bioceramics is a class of materials that have found use as artificial bone materials for repairing or replacing damaged bone tissue because of their excellent biocompatibility and mechanical properties. Bioceramics can also directly interact with the surrounding tissue, either supporting tissue growth or inducing new tissue regeneration. In many biomedical applications, bioceramics such as alumina must often be fabricated to a specific and often complex shape such as artificial hip joints, artificial knee joints, bone screws, maxillofacial reconstruction, dental implants, etc. Alumina oxide is a bioinert material with excellent biocompatibility and mechanical properties, but its high hardness and brittleness make it difficult and costly to machine to the highly complex and precision shapes often required in artificial bone replacements.

Ceramic Injection Moulding is a manufacturing process which can meet many of the requirements for complex geometries and high precision alumina components for artificial bone materials and, where necessary, the alumina parts can be easily machined to the required shape in the green state after injection moulding and prior to sintering. This can result in low-cost custom-made alumina artificial bone structures that match the exact shape of the defective bone being replaced. The CIM alumina parts can also be produced with some porosity to allow cell ingrowth and tissue regeneration.

Research at the Department of Mechanical Systems Engineering, Tokyo Metropolitan University, Japan, has been focused on Ceramic Injection Moulding to produce alumina artificial bone material and, in particular, the research has investigated the effects of CIM conditions, such as alumina powder loading and binder composition and content in the CIM feedstock, in order to control the porosity, grain size and mechanical properties of the sintered CIM alumina material. A paper by T Osada, Y Nagai, and S Kobayashi, recently published in Open Ceramics (Vol. 13, 2023, 100328, 7pp) entitled: ‘Fabrication and mechanical characterization of biocompatible oxide ceramic parts by injection molding’, outlined the results of their research. The authors stated that it is possible to control the density of CIM alumina parts by controlling the binder components and amount of binder added, or adjusting the powder loading. Even if the obtained bending strength of the CIM alumina parts decreased slightly with increasing porosity, they stated it was still found to be sufficient for use as artificial bone material.

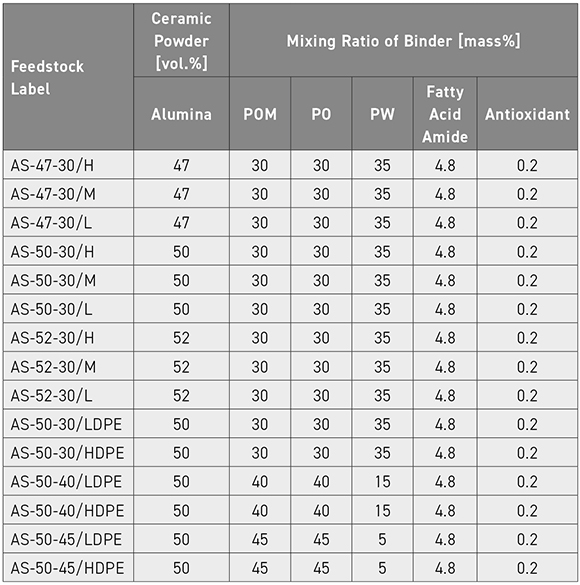

The authors used alumina (Al2O3) powder, to which was added the binder comprising polyacetal (POM) and polyolefin (PO), three types of polypropylene (PP) with different melt flow rates, low-density polyethylene (LDPE) and high-density polyethylene (HDPE)), paraffin wax (PW), fatty acid amide, and an antioxidant. POM and PO acted as the backbone polymers. Powder loading and binder composition are shown in Table 1.

The alumina powder and binders were mixed in a kneader for 1 h at 180°C with powder loading of 47, 50, and 52 vol.%. Viscosity measurements were performed on the feedstock compounds obtained to investigate their rheological behaviour. The authors stated that it was possible to select the powder loading and binder composition according to the viscosity of the sample. In particular, PP has higher strength and lower viscosity than LDPE and HDPE, which they suggest gives it advantages when used to produce artificial bone material from alumina.

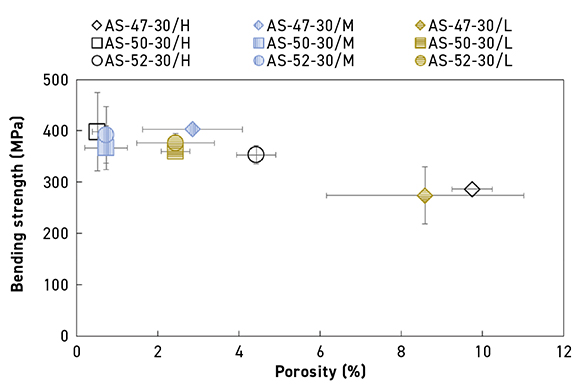

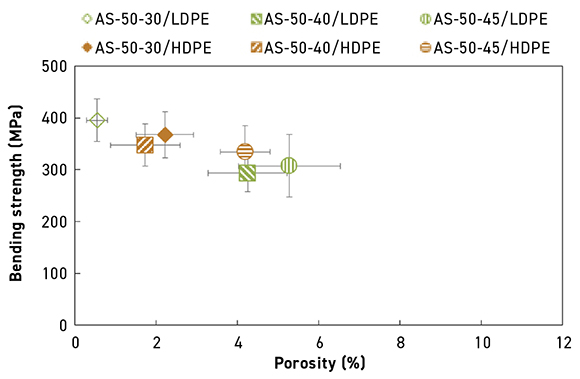

The alumina feedstock was injection moulded into tensile bar shaped specimens. It was established that the optimum conditions for CIM of the alumina feedstock are 50–52 vol.% powder loading or 30–40 mass% in POM/PP and POM/PE in the binder composition. Bending strength was measured on both the green and sintered CIM alumina parts. Fig. 1 shows the relationship between relative density and bending strength in sintered samples, depending on the effect of powder loading, and Fig. 2 shows the same relationship, depending on the different binder compositions used.

The authors reported that the higher viscosity of PP, which has the higher bending strength, makes this binder more suitable when the green CIM parts need to be machined before sintering. The bending strength of LDPE specimens increased with increasing POM and LDPE content. The authors suggested that the molecular weight or content of the backbone polymer affected the strength of green CIM alumina compacts.

Porosity of the sintered CIM alumina parts could be modified by changing the powder loading and porosity could also be increased when needed by increasing the backbone polymer content. Higher powder loading was found to show larger grain sizes in sintered alumina, whereas parts with lower powder loading showed smaller grain size and higher porosity. Bending tests showed fracture occurring along the grain boundaries. The bending strengths of the CIM alumina specimens showed that they were sufficient for use as artificial bone material.

www.sciencedirect.com/journal/open-ceramics

Download PIM International magazine